Development and Application of UHPLC-MS/MS for the Quantification of Bioactive Saponins in Plant Materials

This article provides a comprehensive overview of the UHPLC-MS/MS methodology for the analysis of plant saponins, a class of compounds with significant pharmacological importance.

Development and Application of UHPLC-MS/MS for the Quantification of Bioactive Saponins in Plant Materials

Abstract

This article provides a comprehensive overview of the UHPLC-MS/MS methodology for the analysis of plant saponins, a class of compounds with significant pharmacological importance. It covers the foundational principles of saponin chemistry and the advantages of UHPLC-MS/MS over traditional techniques. A detailed, step-by-step guide for method development is presented, including sample preparation, chromatographic separation, and mass spectrometric detection. The content further addresses critical troubleshooting and optimization strategies to enhance analytical performance and delves into rigorous method validation protocols. Finally, it explores the application of this technology in comparative phytochemical studies, such as assessing the impact of plant processing and geographical origin on saponin profiles, providing a vital resource for researchers and professionals in phytochemistry and drug development.

Saponin Chemistry and the Analytical Power of UHPLC-MS/MS

Structural Classification and Diversity

Saponins are a vast group of non-volatile, surface-active plant secondary metabolites, structurally defined as glycosides consisting of a hydrophobic aglycone (sapogenin) coupled with one or more hydrophilic monosaccharide moieties [1] [2]. This combination of polar and non-polar structural elements explains their soap-like behavior in aqueous solutions [2]. The primary classification of saponins is based on the chemical structure of the sapogenin, dividing them into two major classes: triterpenoid saponins and steroidal saponins [2].

Table 1: Fundamental Characteristics of Triterpenoid and Steroidal Saponins

| Characteristic | Triterpenoid Saponins | Steroidal Saponins |

|---|---|---|

| Sapogenin Carbon Skeleton | Pentacyclic C30 or tetracyclic C30 (Triterpene) [3] [2] | C27 Steroid (derived from cholesterol) [4] [5] |

| Biosynthetic Precursor | 2,3-oxidosqualene (30 carbon atoms) [6] [2] | 2,3-oxidosqualene (with three methyl groups removed) [2] |

| Common Aglycone Examples | Oleanolic acid, Hederagenin, Echinocystic acid [3] [7] | Spirostanol, Furostanol [4] [5] |

| Typical Sugar Attachment Points | Often at C-3 and/or C-28 positions [3] | Often at C-3 and/or C-26 positions [5] |

| Predominant Occurrence | Dicotyledonous plants [4] | Monocotyledonous plants [4] |

Triterpenoid Saponins

Triterpenoid saponins possess an aglycone composed of 30 carbon atoms arranged in a pentacyclic (less commonly tetracyclic) structure [3] [2]. The oleanane-type is one of the most common skeletons [3]. Their structural diversity arises from variations in the sapogenin structure and the composition of the sugar chains, which can be mono-, di-, or tri-saccharides attached at one or more positions, most commonly the C-3 and C-28 hydroxyl groups [3] [7]. Common monosaccharides include glucose, rhamnose, glucuronic acid, arabinose, galactose, and xylose [3] [7].

Steroidal Saponins

Steroidal saponins have an aglycone based on a C27 steroidal skeleton, biogenetically derived from cholesterol [5]. They are primarily categorized into two types:

- Spirostanol saponins: Characterized by a spiroacetal moiety (a tetrahydrofuran ring fused with a tetrahydropyran ring) at C-22 [4] [5].

- Furostanol saponins: Contain a hemiacetal moiety (a single tetrahydrofuran ring) and are often considered biosynthetic precursors to spirostanols [4] [5].

Modifications such as oxidation at various carbon atoms (e.g., C-1, C-12, C-23) and the introduction of double bonds further contribute to their structural complexity [5].

Biosynthesis and Key Enzymes

The biosynthesis of all saponins begins with the mevalonate pathway, leading to the common precursor 2,3-oxidosqualene [6] [2]. This compound is then cyclized by oxidosqualene cyclases (OSCs) into various triterpene or steroidal skeletons [6]. The subsequent structural diversification is primarily mediated by two key enzyme families:

- Cytochrome P450 monooxygenases (P450s): These enzymes catalyze a wide range of oxidation reactions on the sapogenin backbone, including hydroxylation, carboxylation, and epoxidation, thereby creating functional sites for glycosylation [6].

- UDP-dependent glycosyltransferases (UGTs): These enzymes are responsible for attaching sugar moieties to the oxidized aglycone, determining the final glycosylation pattern of the saponin [6].

The following diagram illustrates the core biosynthetic pathway shared by triterpenoid and steroidal saponins.

Detailed UHPLC-MS/MS Protocol for Saponin Quantification

The following section provides a detailed methodology for the simultaneous quantification of specific triterpenoid saponins in plant material, as exemplified by the analysis of Calenduloside E (CE) and Chikusetsusaponin IVa (ChIVa) in Amaranthaceae species [8] [9].

Sample Preparation and Extraction

- Plant Material Handling: Fresh plant material (roots, stems, leaves, fruits) should be lyophilized and ground to a homogeneous powder [9].

- Extraction Techniques:

- Weigh approximately 100 mg of dried powder accurately.

- Employ ultrasound-assisted extraction with 5 mL of 70-80% methanol in water (v/v) for 30-45 minutes at room temperature [9] [10].

- Centrifuge the extracts (e.g., 10,000 × g for 10 minutes) and collect the supernatant.

- Filter the supernatant through a 0.22 μm membrane filter prior to UHPLC-MS/MS analysis [9].

UHPLC-MS/MS Analytical Conditions

The developed method must be validated for specificity, linearity, precision, and accuracy according to ICH guidelines [9] [10].

Table 2: Exemplary UHPLC-MS/MS Conditions for Saponin Quantification

| Parameter | Specification |

|---|---|

| Chromatography System | Ultra-High Performance Liquid Chromatography (UHPLC) |

| Column | Reversed-Phase C18 (e.g., 100 mm x 2.1 mm, 1.7-1.8 μm particle size) |

| Mobile Phase | A: Water with 0.1% Formic AcidB: Acetonitrile |

| Gradient Elution | Linear gradient from 20% B to 95% B over 10-15 minutes [10] |

| Column Temperature | 35 °C [10] |

| Flow Rate | 0.26 - 0.4 mL/min [9] [10] |

| Injection Volume | 1-5 μL |

| Mass Spectrometer | Triple Quadrupole (QqQ) with Electrospray Ionization (ESI) |

| Ionization Mode | Negative Ion Mode (for oleanane-type saponins) [9] |

| Data Acquisition | Multiple Reaction Monitoring (MRM) |

Application: Quantitative Results from Amaranthaceae Species

The validated method was successfully applied to quantify CE and ChIVa in various plant parts of ten Amaranthaceae species [9]. The results demonstrate the variability of saponin content, highlighting rich botanical sources.

Table 3: Distribution of Calenduloside E and Chikusetsusaponin IVa in Selected Amaranthaceae Species (mg/g dry weight) [9]

| Plant Species | Plant Part | Calenduloside E (CE) | Chikusetsusaponin IVa (ChIVa) |

|---|---|---|---|

| Atriplex sagittata | Fruit | 7.84 | 13.15 |

| Chenopodium strictum | Fruit | 6.54 | 5.52 |

| Chenopodium strictum | Roots | Not Specified | 7.77 |

| Lipandra polysperma | Fruit | Not Specified | 12.20 |

| Chenopodium album | Fruit | Not Specified | 10.00 |

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 4: Key Reagent Solutions for Saponin Analysis

| Reagent / Material | Function / Application | Exemplification |

|---|---|---|

| 70-80% Methanol | Extraction solvent for saponins from plant matrices [9]. | Optimal for simultaneous extraction of Calenduloside E and Chikusetsusaponin IVa [9]. |

| Reversed-Phase C18 UHPLC Column | High-efficiency chromatographic separation of saponin isomers [9] [10]. | Enables baseline separation of complex saponin mixtures from Achyranthes bidentata [10]. |

| Ammonium Acetate / Formic Acid | Mobile phase additives to modify pH and improve ionization efficiency in MS [9]. | 0.1% formic acid in water used for UPLC-ESI-MS/MS analysis of triterpenoid saponins [9]. |

| Saponin Reference Standards | Essential for method validation, calibration curves, and compound identification [10]. | Pure Calenduloside E and Chikusetsusaponin IVa are required for accurate quantification [9]. |

| Macroporous Resin (e.g., D101) | Purification and enrichment of saponins from crude plant extracts [3]. | Used for initial clean-up before detailed chromatographic analysis [3]. |

Saponins are a structurally diverse class of plant secondary metabolites with significant pharmaceutical potential, known for their amphiphilic nature due to the presence of hydrophobic aglycone (sapogenin) and hydrophilic sugar moieties [11]. This very combination of structural diversity and polarity presents formidable analytical challenges for researchers aiming to separate, identify, and quantify these compounds in complex plant matrices. Modern analytical techniques, particularly ultra-high-performance liquid chromatography coupled with tandem mass spectrometry (UHPLC-MS/MS), have emerged as powerful tools to address these challenges, enabling comprehensive metabolomic profiling and precise quantification even at trace concentrations [12] [13].

The analysis of saponins is crucial for advancing research on bioactive natural products, as these compounds demonstrate a broad spectrum of pharmacological activities, including anti-tumor, anti-inflammatory, immunomodulatory, and antiviral effects [12] [13]. This application note details the specific challenges associated with saponin analysis and provides structured protocols and workflows developed within the context of a broader thesis on UHPLC-MS/MS method development for saponin quantification in plant research.

The Analytical Challenge: Structural Complexity and Diversity

Saponins are broadly classified into two main groups based on their sapogenin structure: triterpenoid saponins (30 carbon atoms) and steroidal saponins (27 carbon atoms) [14]. This fundamental classification belies an immense structural complexity that directly impacts analytical method development.

The challenges in analysis stem from several factors that create a vast landscape of structurally similar compounds:

- Sapogenin Backbone Variations: The aglycone structure can occur as furostane, spirostane, cholestane, or pregnane skeletons, each with different functional group modifications including hydroxylations, ketones, and double bonds at various positions [15].

- Glycosylation Patterns: Saponins contain 1-6 sugar units, including hexoses (glucose, galactose), deoxyhexoses (rhamnose), pentoses (xylose, arabinose), and uronic acids (glucuronic acid). Isomeric forms arise from the type of sugar, glycosylation position, linkage between sugars, and anomeric configuration [16] [15].

- Acyl Modifications: Further complexity is added by ester-linked acyl groups (acetyl, angeloyl, cinnamyl, or tigloyl) at various positions on the sapogenin or sugar chains [16].

Impact of Polarity on Analysis

The polarity of saponins is primarily governed by the number and nature of the attached sugar units. The hydrophilic sugar moieties make saponins water-soluble, while the lipophilic sapogenin backbone contributes to amphiphilic character [11]. This results in:

- A wide range of hydrophilic-lipophilic balance across different saponins within a single plant extract.

- Challenges in developing a single chromatographic method that effectively separates all structural analogs.

- Difficulties in extraction optimization, as recovery rates are highly dependent on the solvent system's polarity [11].

Table 1: Major Saponin Classes and Their Structural Characteristics

| Saponin Class | Sapogenin Backbone | Carbon Atoms | Common Sugar Attachments | Example Compounds |

|---|---|---|---|---|

| Triterpenoid Saponins | Oleanane, Ursane, Lupane | 30 | GlcA, Glc, Gal, Xyl, Ara, Rha [16] | Soyasaponins [11], Tea Saponins [16], Chikusetsusaponin IVa [13] |

| Steroidal Saponins | Spirostane, Furostane | 27 | Glc, Gal, Rha, Xyl [15] | Polyphyllins [12], Dioscin [12] |

| Steroidal Alkaloids | Solanidane, Spirosolane | 27 | Glc, Gal, Rha, Xyl | - |

Advanced UHPLC-MS/MS Solutions for Saponin Analysis

The combination of UHPLC's high separation power with the selectivity and sensitivity of MS/MS detection is the most effective approach to overcome challenges posed by saponin diversity and polarity.

Chromatographic Optimization and Separation

Successful separation of complex saponin mixtures requires careful optimization of chromatographic conditions:

- Stationary Phase: The Waters ACQUITY UPLC HSS T3 column (1.8 μm, 150 mm × 2.1 mm i.d.) has demonstrated superior separation efficiency for Camellia sinensis seed saponins compared to other C18 columns [17]. For highly polar saponins, Hydrophilic Interaction Liquid Chromatography (HILIC) provides an excellent alternative to reversed-phase chromatography, as demonstrated for soyasaponins in yoghurt alternatives [11].

- Mobile Phase: Acetonitrile is generally preferred over methanol due to lower UV absorption at short wavelengths, improved separation efficiency, and reduced column backpressure [17]. The addition of 0.1% formic acid to both aqueous and organic mobile phases improves peak shape, sensitivity, and retention time reproducibility [17].

- Elution Program: A typical gradient for saponin separation starts with a low organic phase percentage (e.g., 10% acetonitrile) and increases to a high percentage (e.g., 76% acetonitrile) over 10-20 minutes, effectively eluting saponins based on their polarity [16].

Mass Spectrometric Detection and Identification

Mass spectrometry, particularly high-resolution systems like Q-TOF, is indispensable for saponin identification and characterization:

- Ionization Mode: Electrospray Ionization (ESI) in negative mode generally provides superior signal intensity for saponins compared to positive mode [17]. This is particularly effective for saponins containing glucuronic acid residues.

- Fragmentation Patterns: Tandem mass spectrometry (MS/MS) reveals characteristic fragmentation pathways that provide structural information. Key fragmentation patterns include:

- Advanced Identification Strategies: Feature-based Molecular Networking (FBMN) clusters structurally related saponins through systematic analysis of MS/MS spectral data, greatly facilitating the identification of analogs within complex mixtures [16].

Table 2: Key Mass Spectrometric Parameters for Saponin Analysis

| Parameter | Recommended Setting | Rationale | Application Example |

|---|---|---|---|

| Ionization Mode | ESI-Negative | Enhanced signal for most saponin types [17] | Analysis of tea saponins [16] |

| Scan Mode | Full Scan (MS1) + Data-Dependent MS/MS (ddMS2) | Comprehensive profiling and structural info | Untargeted saponin profiling [12] |

| Mass Resolution | High-Resolution (>20,000) | Accurate mass measurement for formula assignment | UPLC-IM-Q-TOF-MS/MS [10] |

| Collision Energy | Ramped (20-50 eV) | Optimized fragmentation across different saponins | Structural characterization [15] |

| Data Analysis | Molecular Networking | Groups structurally related compounds | Tea saponin profiling [16] |

Detailed Experimental Protocols

Sample Preparation and Extraction Protocol

Principle: Efficient extraction of saponins from plant matrices while minimizing degradation and maximizing recovery.

Reagents: Methanol (HPLC grade), acetonitrile (HPLC grade), formic acid, ultrapure water, ammonia solution (5%, v/v).

Procedure:

- Homogenization: Dry plant material (e.g., rhizomes, leaves, seeds) at 60°C and grind to a fine powder that passes through a 3-mesh sieve [12].

- Weighing: Accurately weigh approximately 0.1 g of dried powder into a 2.0 mL centrifuge tube.

- Extraction: Add 1 mL of methanol. Soak the mixture overnight, then perform ultrasonic extraction for 30 minutes [12].

- pH Adjustment (for certain matrices): For acidic food matrices like yoghurt alternatives, adjust the sample pH to 8 ± 0.25 using aqueous ammonia solution to optimize saponin solubility and recovery [11].

- Reconstitution: After cooling to room temperature, adjust the methanol volume to the initial level. Centrifuge at 12,000 × g for 10 minutes.

- Clean-up: Pass the supernatant through a 0.22 μm microporous membrane to obtain the test solution for UHPLC-MS/MS analysis [12].

- Quality Control: Prepare a pooled quality control (QC) sample by combining equal volumes of all test solutions to monitor instrument performance during the analysis sequence.

UHPLC-MS/MS Analytical Protocol

Principle: High-resolution separation and sensitive detection of saponins in plant extracts.

Equipment: UHPLC system coupled to Q-TOF mass spectrometer (e.g., Agilent 1290 Infinity II UHPLC with Agilent 6545 Q-TOF) [12].

Chromatographic Conditions:

- Column: Waters ACQUITY UPLC HSS T3 (1.8 μm, 150 mm × 2.1 mm i.d.) [17] or equivalent C18 column.

- Mobile Phase A: Ultrapure water containing 0.1% formic acid.

- Mobile Phase B: Acetonitrile containing 0.1% formic acid.

- Gradient Program:

- 0-2 min: 10% B

- 2-15 min: 10% B → 76% B (linear gradient)

- 15-17 min: 76% B → 95% B

- 17-19 min: 95% B (column cleaning)

- 19-22 min: 95% B → 10% B (re-equilibration) [16]

- Flow Rate: 0.26 mL/min [10]

- Column Temperature: 30°C

- Injection Volume: 2-5 μL

Mass Spectrometric Conditions:

- Ionization Mode: ESI-negative

- Drying Gas Temperature: 325°C

- Drying Gas Flow: 8 L/min

- Nebulizer Pressure: 40 psi

- Sheath Gas Temperature: 350°C

- Sheath Gas Flow: 11 L/min

- Capillary Voltage: 3500 V

- Nozzle Voltage: 500 V

- Fragmentor Voltage: 180 V

- Scan Range: m/z 100-1700

- Collision Energies: 10-40 eV for MS/MS

Data Processing and Analysis Workflow

Software: Use instrument vendor software and specialized platforms like MS-DIAL or GNPS for molecular networking.

Procedure:

- Peak Picking and Alignment: Perform automated peak detection, deconvolution, and alignment across all samples.

- Compound Identification:

- Match accurate mass and isotopic pattern against databases (e.g., PlantCyc, KNApSAcK).

- Interpret MS/MS spectra for characteristic saponin fragmentation patterns.

- Confirm identities using authentic standards when available.

- Molecular Networking: Upload MS/MS data to the GNPS platform to create molecular networks that visualize structurally related saponins and identify novel analogs [16].

- Multivariate Statistical Analysis: Apply Principal Component Analysis (PCA) and Hierarchical Clustering Analysis (HCA) to identify metabolic patterns and group samples based on their saponin profiles [12].

- Quantitation: Generate calibration curves using reference standards for absolute quantitation, or use peak areas for relative quantitation when standards are unavailable.

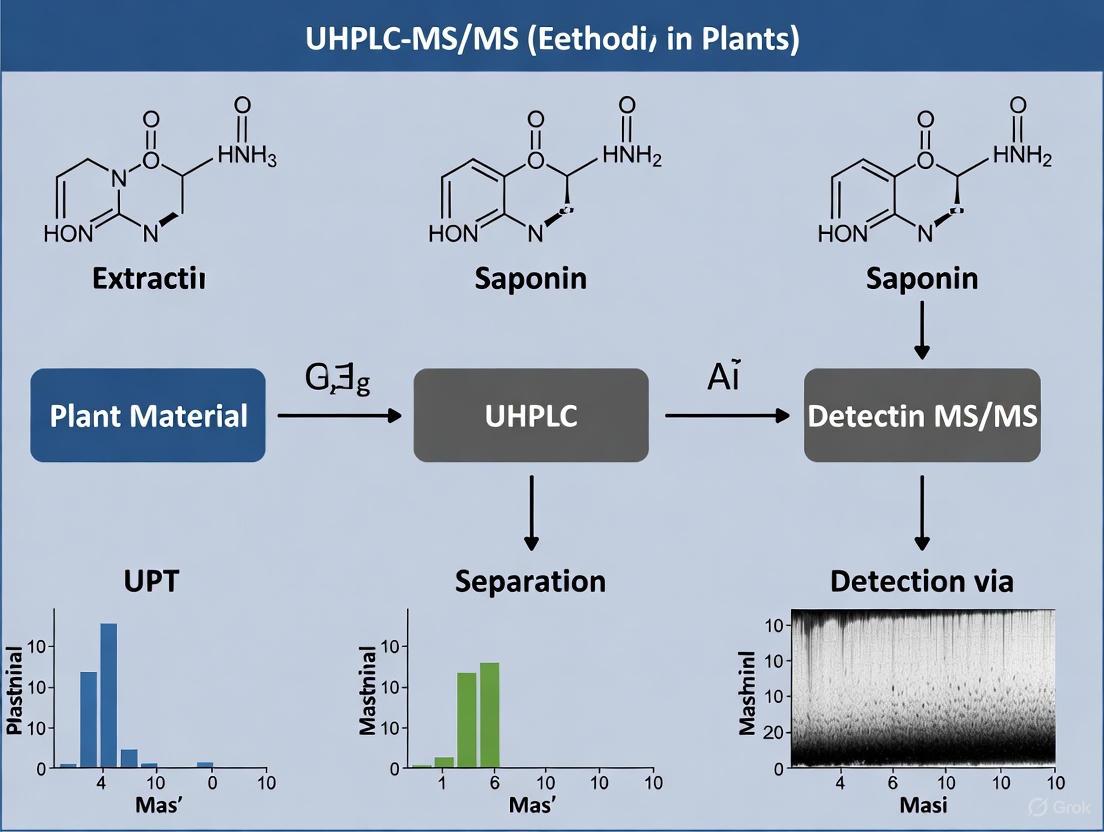

Visualizing the Analytical Workflow

The following diagram illustrates the comprehensive workflow for saponin analysis from sample preparation to data interpretation:

Diagram 1: Comprehensive workflow for saponin analysis in plant materials, covering sample preparation, instrumental analysis, and data interpretation stages.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Reagent Solutions for Saponin Analysis

| Reagent/Material | Function/Purpose | Application Note |

|---|---|---|

| HSS T3 UPLC Column (1.8 μm, 150 mm × 2.1 mm) | Superior separation of complex saponin mixtures [17] | Provides optimal resolution for structural analogs |

| MS-grade Acetonitrile with 0.1% Formic Acid | Mobile phase for UHPLC separation | Enhances ionization and improves peak shape [17] |

| Saponin Reference Standards (e.g., Polyphyllin I, II, VII) | Method validation and absolute quantification | Essential for calibration curves and compound verification [12] |

| Solid Phase Extraction (SPE) Cartridges (e.g., Biotage Isolute PLD+) | Sample clean-up and pre-concentration | Removes interfering matrix components [11] |

| Quality Control (QC) Reference Material (e.g., digitoxin) | Internal standard for relative quantification | Monitors instrument performance and normalizes data [18] |

| Ultrasonic Extraction Bath | Efficient extraction of saponins from plant matrix | Maximizes recovery while minimizing degradation [12] |

The structural diversity and polarity of saponins present significant but surmountable challenges for analytical scientists. Through the implementation of optimized UHPLC-MS/MS methods—incorporating careful sample preparation, advanced chromatographic separation, high-resolution mass spectrometry, and comprehensive data analysis strategies—researchers can effectively navigate this complexity. The protocols and workflows detailed in this application note provide a robust framework for the accurate identification and quantification of saponins in plant materials, supporting ongoing research into their considerable pharmacological potential. Future methodological advances will likely focus on increasing throughput, enhancing sensitivity for trace-level saponins, and improving the structural annotation of novel saponins through integrated computational approaches.

The Evolution from Traditional Methods to Modern Hyphenated Techniques

The quantification of saponins in plant materials has undergone a significant methodological evolution, moving from traditional techniques like open-column chromatography and spectrophotometry to advanced hyphenated systems such as Ultra-High Performance Liquid Chromatography coupled with Tandem Mass Spectrometry (UHPLC-MS/MS). This transition has addressed critical limitations in selectivity, sensitivity, and analytical efficiency. Modern UHPLC-MS/MS methods now enable the simultaneous quantification of multiple bioactive saponins, such as calenduloside E and chikusetsusaponin IVa, even at trace levels in complex plant matrices. These integrated approaches provide researchers with powerful tools for comprehensive quality assessment, authentication of medicinal plants, and accelerated drug development from natural products.

The analysis of bioactive plant compounds, particularly triterpene saponins, presents substantial analytical challenges due to their complex structures, occurrence in intricate plant matrices, and frequently low concentrations despite significant biological activity. Traditional methods, including high-performance liquid chromatography (HPLC) with ultraviolet (UV) or diode-array detection (DAD) and evaporative light scattering detection (ELSD), often proved inadequate for reliable saponin quantification. These techniques were characterized by lengthy analysis times, significant solvent consumption, and poor selectivity, often providing insufficient resolution for structurally similar compounds and isomers [19].

The integration of separation techniques with mass spectrometry, creating "hyphenated systems," marks the most significant advancement in this field. UHPLC-MS/MS combines the superior resolving power of ultra-high-performance liquid chromatography with the exceptional sensitivity and specificity of tandem mass spectrometry. This combination is particularly crucial for saponin analysis, as many triterpene saponins show poor absorbance in the short-wavelength UV range (below 210 nm), preventing their reliable quantification in complex plant extracts using traditional spectroscopic techniques [9]. The evolution to UHPLC-MS/MS has thus become the cornerstone of modern phytochemical analysis, enabling precise quantification and robust quality control for herbal medicines and drug development.

Comparative Analysis of Traditional vs. Modern Techniques

The transition from traditional to modern hyphenated techniques represents a paradigm shift in analytical capabilities. The table below summarizes the key differences in performance characteristics.

Table 1: Comparison of Traditional and Modern Techniques for Saponin Quantification

| Analytical Characteristic | Traditional Methods (HPLC-UV/ELSD) | Modern Hyphenated Techniques (UHPLC-MS/MS) |

|---|---|---|

| Analysis Time | Long analysis times (often >30 minutes) [19] | Short analysis times (e.g., 10 minutes) [19] |

| Sensitivity | Poor sensitivity, especially for non-chromophoric saponins [9] | Exceptional sensitivity (LOD in ng/L range for pharmaceuticals) [20] |

| Selectivity & Specificity | Poor selectivity, relying only on retention time [19] | High specificity using Multiple Reaction Monitoring (MRM) [20] |

| Solvent Consumption | High solvent consumption, resulting in waste [19] | Reduced solvent consumption, aligning with Green Chemistry [20] |

| Data Richness | Limited to retention time and UV spectrum | Provides mass fragments, structural information, and confirmatory data |

| Handling of Isomers | Difficulty separating isomers with identical m/z [19] | Capable of rapid and complete separation of polar isomers [19] |

The advantages of UHPLC-MS/MS extend beyond speed and sensitivity. Its mass-based detection does not depend on the presence of a chromophore, making it ideal for triterpenoid saponins [9]. Furthermore, the technique provides unambiguous identification based on molecular mass and specific fragmentation patterns, minimizing matrix interferences that commonly plague traditional methods [20].

Application Note: UHPLC-MS/MS for Saponin Quantification in Amaranthaceae Species

Background and Objective

Triterpene saponins like calenduloside E (CE) and chikusetsusaponin IVa (ChIVa) exhibit multidirectional bioactivity, including anti-inflammatory, cardioprotective, and neuroprotective effects [9]. Ensuring the efficacy and safety of plant-derived formulations requires accurate quantification of these bioactive compounds. This application note details a validated UHPLC-ESI-MS/MS method for the simultaneous quantification of CE and ChIVa in various plant parts of ten Amaranthaceae species, demonstrating the power of modern hyphenated techniques in phytochemical analysis.

Experimental Protocol

Sample Preparation and Extraction

- Plant Material: Roots, stems, leaves, and fruits from ten wild-growing Amaranthaceae species were collected and authenticated [9].

- Extraction Optimization: Four extraction methods were compared: maceration, shaking-assisted maceration, ultrasound-assisted extraction (UAE), and heat reflux extraction. UAE was determined to be optimal for the studied saponins [9].

- Optimized UAE Procedure:

- Solvent: Ethanol-H₂O (1:1, v/v) [21].

- Solvent-to-Sample Ratio: 1:8 [21].

- Extraction Process: Perform extraction 3 times, each for 30 minutes [21].

- Post-Extraction: The extract is subjected to liquid-liquid partitioning with petroleum ether followed by saturated n-butanol. The n-butanol fraction is concentrated and further purified using AB-8 macroporous resin column chromatography with ethanol-H₂O (7:3, v/v) as the eluent to enrich the saponin fraction [21].

UHPLC-MS/MS Analysis

- Chromatography:

- System: Ultra-High Performance Liquid Chromatography (UHPLC).

- Mobile Phase: Acetonitrile/water system with 0.3% acetic acid added to the water phase to enhance ionization and improve peak shape of the analytes [19].

- Gradient: Optimized gradient program to achieve satisfactory separation within a short analysis time [19] [9].

- Mass Spectrometry:

- Technique: Tandem Mass Spectrometry (MS/MS).

- Ionization: Electrospray Ionization (ESI), typically in negative mode for saponins, yielding intense deprotonated molecular ions [M−H]⁻ [21].

- Mode: Multiple Reaction Monitoring (MRM) for high sensitivity and selectivity. The method was developed and validated to be specific for CE and ChIVa, guaranteeing well-shaped peaks and appropriate resolution [9].

Method Validation

The developed UHPLC-MS/MS method was validated according to standard guidelines to ensure reliability, with results satisfying acceptance criteria [9]:

- Precision: Intra-day and inter-day variations (RSD) were desirably low, e.g., 1.57–2.46% and 1.51–3.00%, respectively, in a similar study [19].

- Accuracy: Recovery rates were demonstrated to be high, for instance, ranging from 98.58–101.48% in a related method [19].

- Linearity: The method demonstrated a linear response with correlation coefficients (R²) ≥ 0.999 [20].

- Specificity: The method was found to be selective for the investigated compounds, free from interference [9].

Key Research Reagent Solutions

Table 2: Essential Reagents and Materials for UHPLC-MS/MS Saponin Analysis

| Reagent/Material | Function/Application | Example from Protocol |

|---|---|---|

| Acetonitrile (HPLC-MS Grade) | Mobile phase component for UHPLC separation | Used in acetonitrile/water mobile phase system [19] |

| Acetic Acid | Mobile phase modifier to enhance analyte ionization | Added at 0.3% to water phase to increase signal intensity [19] |

| Ethanol & Purified Water | Extraction solvent for ultrasound-assisted extraction | Used as ethanol-H₂O (1:1, v/v) for saponin extraction [21] |

| AB-8 Macroporous Resin | Stationary phase for pre-cleaning and enriching saponins | Used in column chromatography to enrich saponin fraction [21] |

| Analytical Standards | Calibration and quantification reference | Calenduloside E and Chikusetsusaponin IVa pure standards [9] |

Results and Data Presentation

The validated method was successfully applied to quantify CE and ChIVa in different plant parts. The results highlighted significant interspecies and intraspecies variation in saponin content.

Table 3: Quantification of Calenduloside E (CE) and Chikusetsusaponin IVa (ChIVa) in Selected Amaranthaceae Species (mg/g dry weight) [9]

| Species | Plant Part | Calenduloside E (CE) | Chikusetsusaponin IVa (ChIVa) |

|---|---|---|---|

| A. sagittata | Fruit | 7.84 | 13.15 |

| L. polysperma | Fruit | Not Specified | 12.20 |

| Ch. album | Fruit | Not Specified | 10.00 |

| Ch. strictum | Roots | Not Specified | 7.77 |

| Ch. strictum | Fruit | 6.54 | 5.52 |

The data obtained demonstrates the utility of the UHPLC-MS/MS method for identifying rich sources of bioactive saponins. For instance, the fruit of A. sagittata was identified as a particularly convenient source of both CE and ChIVa [9]. Furthermore, this was the first report of CE and ChIVa in several species, including L. polysperma and A. patula [9].

Workflow and Data Interpretation Visualizations

UHPLC-MS/MS Saponin Analysis Workflow

Saponin Identification via Tandem Mass Spectrometry

The evolution from traditional chromatographic methods to modern hyphenated techniques like UHPLC-MS/MS has fundamentally transformed the landscape of saponin research. This advanced methodology provides an unparalleled combination of speed, sensitivity, and specificity, enabling the precise quantification of complex plant metabolites that were previously difficult to analyze. The successful application of UHPLC-MS/MS for profiling calenduloside E and chikusetsusaponin IVa across multiple Amaranthaceae species underscores its critical role in modern phytochemistry, quality control of herbal medicines, and the discovery of new plant-derived pharmaceutical compounds. As this technology continues to evolve alongside green chemistry principles, it will undoubtedly remain the gold standard for analytical scientists in natural product research and drug development.

Saponins are a diverse class of secondary metabolites found extensively in medicinal plants, known for their complex chemical structures and broad pharmacological activities, including anti-inflammatory, anticancer, antiviral, and cardioprotective effects. The analysis of these compounds presents significant challenges due to their structural diversity, low UV absorption, isomeric complexity, and frequently low concentrations within complex plant matrices. Additionally, saponins often occur as a series of analogues with nearly identical structures, differing only in their glycosylation patterns or slight modifications to the aglycone moiety. Ultra-High-Performance Liquid Chromatography coupled with Tandem Mass Spectrometry (UHPLC-MS/MS) has emerged as a powerful analytical platform that effectively addresses these challenges by combining high-resolution separation with selective and sensitive detection.

Core Analytical Challenges and UHPLC-MS/MS Solutions

Challenge 1: Structural Complexity and Isomer Separation

Saponins exhibit extensive structural complexity with numerous isomers that have identical molecular formulas but differ in sugar linkage types, positions, and stereochemistry. Traditional HPLC methods often lack the resolution to separate these compounds adequately.

UHPLC-MS/MS Solution: The use of sub-2µm particle columns in UHPLC provides superior chromatographic resolution and peak capacity. The enhanced efficiency allows for the separation of structurally similar saponins, such as calenduloside E (CE) and chikusetsusaponin IVa (ChIVa), which share oleanolic acid as an aglycone but differ by an additional glucose moiety ester-linked at the C-17 position in ChIVa [13] [9]. The high peak capacity of UHPLC systems enables resolution of these challenging compounds within significantly reduced analysis times.

Table 1: Representative Chromatographic Conditions for Saponin Separation

| Parameter | Condition 1 [13] | Condition 2 [22] | Condition 3 [23] |

|---|---|---|---|

| Column | Not specified | Agilent Zorbax SB-18 MS (3.0 × 50 mm, 1.8 µm) | Supelco C18 (3.0 × 50 mm, 2.7 µm) |

| Mobile Phase | Acetonitrile/0.1% formic acid | 0.1% formic acid in water (A) and methanol (B) | Acetonitrile (A) and 0.1% formic acid in water (B) |

| Gradient | Optimized for specific separation | 10-65% B (0-3 min), 65% B (3-6 min), 65-90% B (6-9 min) | 15% A (2 min), to 30% A (13 min), to 95% A (10 min) |

| Flow Rate | Not specified | 0.5 mL/min | 0.5 mL/min |

| Analysis Time | Rapid analysis achieved | 13 min total run time | 35 min total run time |

Challenge 2: Detection Sensitivity and Selectivity

Triterpene saponins typically show poor absorbance in the short-wavelength UV range (below 210 nm), which often prevents their reliable detection and quantification in complex plant extracts using conventional UV or DAD detectors [13] [9].

UHPLC-MS/MS Solution: Mass spectrometric detection provides exceptional sensitivity and selectivity independent of chromophore presence. The multiple reaction monitoring (MRM) mode available in triple quadrupole instruments offers unparalleled specificity by monitoring specific precursor-to-product ion transitions for each analyte. This effectively filters out matrix interference, enabling precise quantification even at trace levels. The limits of detection (LOD) and quantification (LOQ) reported for saponin analysis demonstrate remarkable sensitivity, with LODs ranging from 0.20 to 0.61 ng/mL and LOQs from 0.61 to 1.85 ng/mL in validated methods [24].

Challenge 3: Comprehensive Profiling in Complex Matrices

Plant extracts represent highly complex mixtures containing thousands of compounds with varying polarities and concentrations, creating significant matrix effects that can suppress or enhance ionization and compromise accurate quantification.

UHPLC-MS/MS Solution: The combination of high-resolution chromatographic separation with advanced mass spectrometric detection enables comprehensive profiling of saponins in complex plant materials. The two-stage mass spectrometry approach utilizes high-resolution instruments like Q-TOF for qualitative identification of novel saponins, followed by highly sensitive QQQ systems for precise quantification [22]. This integrated strategy was successfully applied to profile 63 saponins in different morphological regions of American ginseng, identifying marker compounds specific to main roots, lateral roots, and rhizomes [23].

Figure 1: Experimental workflow for saponin analysis in plant materials

Detailed Experimental Protocols

Sample Preparation and Extraction

Protocol 1: Standardized Extraction Procedure [13] [23]

- Plant Material Preparation: Separate fresh plant material into different morphological regions (main root, lateral root, rhizome, stem, leaves, fruits). Air-dry at 25-30°C, grind to fine powder, and sieve for uniform particle size.

- Extraction: Accurately weigh 0.1 g of fine powder into a suitable container. Add 4 mL of 70% methanol-water (v/v) extraction solvent.

- Sonication: Sonicate the mixture for 45 minutes at room temperature with controlled power settings.

- Filtration: Pass the extraction through a 0.22 μm membrane filter prior to UHPLC-MS/MS analysis.

- Alternative Methods: For comparative extraction efficiency, maceration, shaking-assisted maceration, and heat reflux extraction can be evaluated alongside ultrasound-assisted extraction [13].

Protocol 2: Tissue Distribution Studies [25]

- Biological Sample Preparation: Homogenize tissue samples (liver, kidney, heart, spleen) with appropriate buffer.

- Protein Precipitation: Employ a one-step protein precipitation using methanol for sample clean-up.

- Internal Standard Addition: Add chloramphenicol or glycyrrhetinic acid as internal standards to monitor extraction efficiency and matrix effects.

- Centrifugation: Centrifuge at high speed (≥10,000 × g) for 10 minutes and collect supernatant for analysis.

UHPLC-MS/MS Instrumental Conditions

Chromatographic System: [13] [22] [23]

- Column: C18 reversed-phase columns (50-100 mm length × 2.1-3.0 mm i.d., 1.8-2.7 µm particle size)

- Mobile Phase: Binary gradient systems combining (A) 0.1% formic acid in water and (B) acetonitrile or methanol with 0.1% formic acid

- Gradient Program: Optimized linear gradients ranging from 5-15% B to 90-100% B over 5-15 minutes

- Flow Rate: 0.3-0.5 mL/min

- Column Temperature: 35-40°C

- Injection Volume: 5-10 µL

Mass Spectrometric Detection: [26] [13] [22]

- Ionization Source: Electrospray Ionization (ESI) operating in negative or positive mode, depending on analyte characteristics

- Ion Source Parameters: Capillary voltage: 3.0-3.5 kV; Drying gas temperature: 300-350°C; Sheath gas flow: 8-12 L/min

- Scan Modes:

- Qualitative Analysis: Full scan and data-dependent MS/MS using Q-TOF instruments for structural elucidation

- Quantitative Analysis: Multiple Reaction Monitoring (MRM) using triple quadrupole instruments for sensitive quantification

- Collision Energies: Optimized individually for each analyte (typically 20-45 eV)

Figure 2: MRM detection principle for selective saponin quantification

Method Validation Parameters

Comprehensive validation following ICH guidelines ensures method reliability, with key parameters including:

- Linearity: Correlation coefficients (r²) > 0.99 over relevant concentration ranges [24] [26]

- Precision: Intra-day and inter-day precision with RSD < 5% [24] [26]

- Accuracy: Recovery rates of 88.3-104.8% for various matrices [24] [26] [25]

- Sensitivity: LOD and LOQ values in ng/mL range [24]

- Matrix Effects: Evaluation of ion suppression/enhancement with acceptable RSD values [26]

Table 2: Validation Data from Representative Saponin Quantification Methods

| Validation Parameter | Chenopodium bonus-henricus Method [24] | Achyranthes bidentata Method [26] | Dipsacus asper Method [25] |

|---|---|---|---|

| Linearity (R²) | > 0.99 | > 0.9998 | > 0.9991 |

| LOD Range | 0.20-0.61 ng/mL | Not specified | Not specified |

| LOQ Range | 0.61-1.85 ng/mL | 20.4-8500 ng/mL | Not specified |

| Precision (RSD) | Intra-day: 0.64-4.25% | Intra-day: < 3.95% | Intra-day: -4.62 to 4.93% |

| Accuracy (% Recovery) | 95.38-103.47% | 95.2-104.8% | 88.3-100.1% |

| Analysis Time | Significantly reduced | Not specified | Not specified |

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Reagent Solutions for Saponin Analysis

| Item | Function/Purpose | Examples/Specifications |

|---|---|---|

| UHPLC Columns | High-resolution separation of saponins | C18 reversed-phase (50-100mm, 1.8-2.7µm); Waters BEH C18 [26] |

| Mass Spectrometry Instruments | Sensitive detection and quantification | Triple quadrupole (QQQ) for MRM quantification; Q-TOF for structural identification [22] [23] |

| Reference Standards | Method development, calibration, identification | β-ecdysterone, ginsenoside Ro, chikusetsusaponin IV, calenduloside E [26] [13] |

| Internal Standards | Correction for matrix effects, recovery calculation | Chloramphenicol, glycyrrhetinic acid [13] [25] |

| Extraction Solvents | Efficient extraction of saponins from plant material | 70% methanol-water, ethanol-water (4:1, v/v) [13] [23] |

| Mobile Phase Additives | Improve chromatography and ionization | 0.1% formic acid in water and organic phase [26] [22] [23] |

Application Examples in Plant Research

Phytochemical Distribution Studies

UHPLC-MS/MS enables precise mapping of saponin distribution across different plant parts. In studies of Amaranthaceae species, the highest chikusetsusaponin IVa content was found in the fruit of A. sagittata (13.15 mg/g dw), L. polysperma (12.20 mg/g dw), and C. album (10.0 mg/g dw), while the highest calenduloside E content was determined in the fruit of A. sagittata (7.84 mg/g dw) and C. strictum (6.54 mg/g dw) [13]. Such distribution studies help identify optimal plant parts and harvesting times for maximum saponin yield.

Pharmacokinetic and Bioavailability Studies

The high sensitivity of UHPLC-MS/MS enables pharmacokinetic studies of saponins in biological matrices. A comparative study of raw and salt-processed Achyranthes bidentata revealed that salt-processing significantly increased the bioavailability of β-ecdysterone, 25S-inokosterone, ginsenoside Ro, and chikusetsusaponin IVa, as evidenced by elevated Cmax and AUC0-t parameters [26]. Similarly, tissue distribution studies of Dipsacus asper constituents demonstrated that wine-processing altered the disposition of bioactive compounds, leading to increased accumulation in liver and kidney tissues, which correlates with enhanced therapeutic effects on these organs [25].

Chemotaxonomic and Metabolomic Studies

The technique supports chemotaxonomic classifications by revealing genus-specific and species-specific saponin profiles. Metabolomic studies of Banisteriopsis and Stigmaphyllon genera using UHPLC-QTOF-MS/MS revealed distinct chemical profiles influenced by environmental factors, humidity levels, and plant habit, with discriminant metabolites including coumaroyl hexoside, myricetin-3-galactoside, and quercetin derivatives [27]. Such comprehensive profiling provides valuable insights for phylogenetic studies and quality control of medicinal plants.

UHPLC-MS/MS has revolutionized saponin analysis by effectively addressing the core challenges of structural complexity, low detection sensitivity, and matrix interference. The integration of high-resolution chromatographic separation with advanced mass spectrometric detection provides researchers with a powerful tool for qualitative and quantitative analysis of these biologically significant compounds. As evidenced by the diverse applications in phytochemistry, pharmacognosy, and pharmacokinetics, this analytical platform continues to drive advancements in natural product research, enabling more comprehensive characterization of medicinal plants and facilitating quality control in phytopharmaceutical development.

The analysis of plant saponins represents a significant challenge in natural product research due to the structural complexity and diversity of these bioactive compounds. Ultra-High Performance Liquid Chromatography coupled with Tandem Mass Spectrometry (UHPLC-MS/MS) has emerged as a powerful analytical platform that enables researchers to address key challenges in saponin quantification, identification, and dereplication within complex plant matrices. This technology provides the sensitivity, resolution, and speed required to analyze these often closely-related compounds in plant extracts, supporting research from basic phytochemical characterization to drug discovery applications.

The fundamental advantage of UHPLC-MS/MS lies in its ability to separate complex mixtures with high efficiency while providing structural information through mass spectrometry. For saponins, which frequently lack strong chromophores and exhibit poor UV absorption, the MS/MS detection offers superior sensitivity and specificity compared to conventional UV-based detection methods [9]. This technical capability has become increasingly valuable as research continues to reveal the multifaceted bioactivities of saponins, including their anti-inflammatory, anti-tumor, neuroprotective, and cardioprotective effects [9] [28].

Key Application Areas

Quantitative Analysis of Bioactive Saponins

Targeted quantification of specific, biologically relevant saponins represents a cornerstone application of UHPLC-MS/MS in phytochemical research. The technology enables precise measurement of individual saponins across different plant species, tissues, and cultivation conditions, providing critical data for assessing plant material quality and selecting optimal sources for further development.

A recent investigation into ten wild-growing species of Amaranthaceae exemplifies this approach, focusing on the simultaneous quantification of two oleanolic acid-type saponins: calenduloside E (CE) and chikusetsusaponin IVa (ChIVa) [9]. The study developed and validated a specific UPLC-ESI-MS/MS method that achieved appropriate peak resolution, repeatability, and shortened analysis time. This methodological rigor enabled the discovery that these saponins coexist in most species analyzed, with particularly high concentrations found in specific plant organs, thereby identifying promising sources for these bioactive compounds [9].

Table 1: Distribution of Calenduloside E and Chikusetsusaponin IVa in Selected Amaranthaceae Species

| Species | Plant Part | Calenduloside E (mg/g dw) | Chikusetsusaponin IVa (mg/g dw) |

|---|---|---|---|

| A. sagittata | Fruit | 7.84 | 13.15 |

| L. polysperma | Fruit | Not specified | 12.20 |

| Ch. album | Fruit | Not specified | 10.00 |

| Ch. strictum | Roots | Not specified | 7.77 |

| Ch. strictum | Fruit | 6.54 | 5.52 |

The quantitative data revealed significant variation in saponin content between species and plant parts, highlighting the importance of selective harvesting and the value of UHPLC-MS/MS in guiding these decisions. For instance, fruits of A. sagittata accumulated the highest levels of both CE (7.84 mg/g dw) and ChIVa (13.15 mg/g dw), identifying this species and tissue as particularly valuable for obtaining these saponins [9].

Comprehensive Profiling and Dereplication of Saponins

Beyond targeted quantification, UHPLC-MS/MS serves as an essential tool for untargeted profiling and dereplication of complex saponin mixtures in plant extracts. Dereplication—the rapid identification of known compounds in complex mixtures—is crucial for avoiding redundant research and prioritizing novel bioactive constituents.

The integration of molecular networking with UHPLC-HRMS/MS has significantly advanced dereplication strategies for natural products [29]. This approach visualizes complex MS/MS data as molecular families, grouping structurally related compounds based on similar fragmentation patterns. In a study on Hypericum species, molecular networking efficiently clustered polycyclic polyprenylated acylphloroglucinols (PPAPs), enabling rapid comparison of chemical compositions between species and annotation of both known and potentially novel compounds [29].

Advanced LC configurations further enhance separation power for complex saponin mixtures. An offline HILIC × RP LC/QTOF-MS system demonstrated exceptional utility in characterizing triterpene saponins from Rhizoma Panacis Japonici (RPJ) [30]. This two-dimensional separation approach significantly increased peak capacity to 1,249, with an orthogonality of 0.61, enabling the characterization of 307 saponins—76 of which were identified for the first time in Panax japonicus [30]. The integration of an in-house database containing 612 known saponins from the Panax genus and 228 predicted metabolites facilitated efficient annotation of the detected compounds.

Table 2: Saponin Characterization in Herbal Medicines Using Advanced UHPLC-MS/MS Approaches

| Herbal Medicine | Analytical Approach | Number of Saponins Characterized | Novel Identifications | Reference |

|---|---|---|---|---|

| Rhizoma Panacis Japonici | Offline HILIC × RP LC/QTOF-MS | 307 | 76 | [30] |

| Achyranthes bidentata | UHPLC-ELSD / UPLC-IM-Q-TOF-MS/MS | 9 (quantified) | 2 new triterpenoid saponins | [10] |

| Lilium lancifolium | NADES-UHPLC-MS/MS | 9 target steroidal saponins | 31 total compounds identified | [31] |

Bioanalytical Applications

UHPLC-MS/MS also finds critical application in pharmacokinetic and bioavailability studies of saponins, which often exhibit poor absorption and complex metabolism. A validated LC-MS/MS method for quantifying 20(S)-protopanaxadiol (PPD)—a saponin derivative with potent biological activities—demonstrated the application of this technology across multiple biological matrices, including plasma, tissues, bile, urine, and fecal samples [32]. The method achieved a low quantification limit of 2.5 ng/mL and was successfully applied to kinetic studies in both rats and dogs, providing comprehensive absorption, distribution, metabolism, and excretion (ADME) profiles [32].

Experimental Protocols

Protocol 1: UPLC-ESI-MS/MS Method for Simultaneous Saponin Quantification

This protocol describes the simultaneous quantification of calenduloside E and chikusetsusaponin IVa in plant material, adapted from the validated method reported for Amaranthaceae species [9].

Sample Preparation:

- Extraction Optimization: Compare extraction techniques (maceration, shaking-assisted maceration, ultrasound-assisted extraction, and heat reflux extraction) to determine optimal conditions for target saponins.

- Plant Material Processing: Lyophilize and pulverize plant material to a fine powder. Precisely weigh 100 mg of powder for extraction.

- Extraction Procedure: Extract with 5 mL of suitable solvent (e.g., methanol-water mixture) using the optimized extraction method.

- Sample Cleanup: Centrifuge at 10,000 × g for 10 minutes and filter through a 0.22 μm membrane prior to UHPLC-MS/MS analysis.

UHPLC-MS/MS Analysis:

- Chromatographic Conditions:

- Column: Acquity UPLC BEH C18 (100 mm × 2.1 mm, 1.7 μm)

- Mobile Phase: A) 0.1% formic acid in water; B) 0.1% formic acid in acetonitrile

- Gradient: 5-95% B over 10 minutes

- Flow Rate: 0.4 mL/min

- Column Temperature: 40°C

- Injection Volume: 2 μL

Mass Spectrometry Parameters:

- Ionization Mode: Electrospray ionization (ESI) in negative mode

- Ion Source Temperature: 150°C

- Desolvation Temperature: 500°C

- Cone Gas Flow: 50 L/h

- Desolvation Gas Flow: 1000 L/h

- Multiple Reaction Monitoring (MRM) transitions optimized for each saponin

Method Validation:

- Establish linearity, precision, accuracy, limit of detection (LOD), and limit of quantification (LOQ) according to ICH guidelines.

- Determine specificity by analyzing blank samples and assessing potential interference.

- Evaluate extraction recovery and matrix effects.

Protocol 2: Molecular Networking for Saponin Dereplication

This protocol outlines the creation and analysis of molecular networks for saponin dereplication, adapted from studies on Hypericum and Gliricidia sepium [29] [33].

Sample Preparation and Data Acquisition:

- Extract Preparation: Prepare comprehensive plant extracts using 70% ethanol or other appropriate solvents.

- UHPLC-QTOF-MS/MS Analysis:

- Column: Kinetex phenyl-hexyl (1.7 μm, 2.1 × 50 mm) or similar

- Mobile Phase: A) 0.1% formic acid in water; B) 0.1% formic acid in acetonitrile

- Gradient: 5-100% B over 15 minutes

- Data Acquisition: Use data-dependent acquisition (DDA) or data-independent acquisition (DIA) modes

- Mass Range: 100-1500 m/z

Molecular Networking Workflow:

- Data Conversion: Convert raw data to open formats (e.g., mzML) using MSConvert.

- Feature Detection: Use MZmine or XCMS for feature detection and alignment.

- GNPS Analysis:

- Upload MS/MS data to the GNPS platform (http://gnps.ucsd.edu)

- Set parameters: minimum pairs cosine score 0.7, fragment ion mass tolerance 0.02 Da

- Create molecular network using molecular networking workflow

- Network Visualization and Analysis:

- Import network data into Cytoscape for visualization

- Identify clusters of structurally related saponins

- Annotate nodes using spectral library matches and in-house databases

Advanced Dereplication:

- In-House Database Creation: Compile known saponins from literature and predicted metabolites based on common substitutions.

- Fragmentation Pattern Analysis: Study characteristic fragmentation pathways of saponin classes.

- Targeted Isolation: Prioritize unknown clusters for further isolation and structural elucidation.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Research Reagents and Materials for Saponin Analysis by UHPLC-MS/MS

| Category | Item | Specification/Function | Application Examples |

|---|---|---|---|

| Chromatography | UHPLC System | High-pressure capable (≥15,000 psi) | All separation applications |

| C18 Column | 1.7-1.8 μm particle size, 100 × 2.1 mm | Primary reversed-phase separation [9] | |

| HILIC/Amide Column | For orthogonal separation | 2D-LC applications [30] | |

| Mass Spectrometry | QTOF Mass Spectrometer | High resolution (>30,000) and mass accuracy (<5 ppm) | Untargeted profiling, dereplication [29] [33] |

| Tandem Quadrupole | Multiple reaction monitoring (MRM) capability | Targeted quantification [9] [32] | |

| ESI Ion Source | Electrospray ionization in negative/positive mode | Optimal saponin ionization [9] | |

| Reference Standards | Saponin Standards | High-purity (>95%) reference compounds | Method validation, quantification [9] [10] |

| Internal Standards | Stable isotope-labeled or structural analogs | Quantification normalization [32] | |

| Extraction Materials | Natural Deep Eutectic Solvents | Green extraction alternative | Enhanced saponin extraction [31] |

| Solid Phase Extraction | Cartridges for sample cleanup | Matrix complexity reduction |

Visualization of Key Workflows

Two-Dimensional LC-MS Workflow for Comprehensive Saponin Characterization

Integrated Dereplication Strategy for Saponin Discovery

UHPLC-MS/MS technologies have revolutionized saponin research by providing powerful tools for quantification, profiling, and dereplication. The applications outlined in this document—from targeted quantification of specific bioactive saponins to comprehensive characterization of complex saponin mixtures—demonstrate the versatility and power of these analytical platforms. As research continues to uncover the pharmacological potential of plant saponins, these methodologies will play an increasingly critical role in accelerating natural product discovery and development, ultimately supporting the creation of new therapeutic agents from plant sources.

A Step-by-Step Guide to UHPLC-MS/MS Method Development for Saponins

The precision of any Ultra-High Performance Liquid Chromatography-Tandem Mass Spectrometry (UHPLC-MS/MS) method for saponin quantification is fundamentally dependent on the initial sample preparation stages. Extraction efficiency and selectivity are paramount, as they directly influence the sensitivity, accuracy, and reproducibility of the final analytical results. Saponins, being amphipathic glycosides with diverse chemical structures and polarities, present a significant challenge for efficient extraction from complex plant matrices [28] [34]. This application note, framed within a broader thesis on UHPLC-MS/MS method development, provides a detailed protocol for optimizing extraction solvents and techniques for saponin analysis, leveraging the most recent advancements in green chemistry and analytical science.

State of the Art in Saponin Extraction

The field of saponin extraction has progressively evolved from traditional methods like maceration and reflux extraction towards more efficient, environmentally sustainable techniques [28]. The current landscape is characterized by a shift to methods that enhance mass transfer, reduce solvent consumption, and improve selectivity.

Table 1: Comparison of Modern Saponin Extraction Techniques

| Extraction Technique | Key Principle | Optimal Conditions for Saponins | Key Advantages | Reported Performance |

|---|---|---|---|---|

| Ultrasound-Assisted Extraction (UAE) | Uses ultrasonic waves to cavitate cells, enhancing solvent penetration. | Ethanol concentration: 40-60%; Time: 89 min [35]. | Reduced extraction time and solvent volume; improved efficiency over maceration. | Higher extraction rate compared to traditional maceration [34]. |

| Microwave-Assisted Extraction (MAE) | Microwave energy heats solvents and plant tissues internally, causing cell rupture. | Not specified in results. | Rapid heating; reduced solvent volume; high sample throughput. | Alternative to conventional methods with increased throughput [34]. |

| Natural Deep Eutectic Solvents (NADES) | Uses mixtures of HBDs and HBAs to form a solvent with high solubility for target compounds. | Choline Chloride: 1,2-Propylene glycol (1:1); Water content: 40% [35]. | Green, tunable solvent; high extraction yield and selectivity; biodegradability. | 46.6 mg/g from Lilium lancifolium vs. lower yield for ethanol [31]. |

| Ionic Liquid-Based UAE (IL-UAE) | Combines ionic liquids with ultrasonication. | Specific ILs tailored to target saponins. | High extraction efficiency; significantly shortened extraction time. | Higher efficiency and shorter time vs. traditional UAE [34]. |

The selection of the extraction solvent is equally critical. While conventional solvents like methanol and ethanol are widely used, Natural Deep Eutectic Solvents (NADES) have emerged as a superior green alternative. NADES are typically composed of natural primary metabolites, such as choline chloride (a hydrogen bond acceptor, HBA) and organic acids, sugars, or alcohols (hydrogen bond donors, HBD), which form a low-temperature eutectic mixture through hydrogen bonding [31]. Their advantages include low toxicity, biodegradability, low cost, and tunable physicochemical properties, allowing for customization to extract a wide range of saponin polarities [31] [35]. For instance, a study on Lilium lancifolium demonstrated that a NADES composed of choline chloride and anhydrous citric acid (2:1) yielded a total saponin content of 46.6 mg/g, significantly surpassing the yield obtained with conventional ethanol extraction [31].

Detailed Experimental Protocols

Protocol 1: Optimization of Saponin Extraction fromPanaxLeaves Using Response Surface Methodology

This protocol, adapted from recent research, details a systematic approach to optimizing the extraction of triterpenoid saponins from Panax notoginseng leaves (PNL) and Panax quinquefolium leaves (PQL) [36].

3.1.1 Materials and Reagents

- Dried, powdered leaves of Panax notoginseng (PNL) or Panax quinquefolium (PQL).

- Ethanol solutions (0% to 99.70%, v/v).

- Vanillin, perchloric acid, sulfuric acid, and glacial acetic acid (for colorimetric analysis).

- Distilled or deionized water.

3.1.2 Equipment

- Analytical balance.

- UV-Vis spectrophotometer.

- Centrifuge.

- Ultrasonic bath or shaker.

- Water bath.

3.1.3 Single-Factor Experimentation The first step involves a single-factor experiment to identify the preliminary range of key variables. For each factor listed below, keep the others constant.

- Ethanol Concentration: Extract 1 g of sample with 20 mL of ethanol at concentrations of 0%, 20%, 40%, 60%, 80%, and 99.70% (v/v) for 36 hours.

- Solid-Liquid Ratio: Extract 1 g of sample with ethanol at the optimal concentration from step 1, using ratios of 1:5, 1:10, 1:15, 1:20, 1:25, and 1:30 (g:mL) for 36 hours.

- Extraction Time: Extract 1 g of sample with the optimal ethanol concentration and solid-liquid ratio for 12, 24, 36, 48, 60, and 72 hours.

After each extraction, centrifuges the samples, collect the supernatant, and determine the total saponin content using the vanillin-sulfuric acid colorimetric method. Measure the absorbance at 548 nm and calculate the content using a pre-established standard curve (e.g., C = 349.93x - 9.9272, R² = 0.9993) [36].

3.1.4 Response Surface Methodology (RSM) Optimization Based on the single-factor results, a three-factor, three-level Box-Behnken Design (BBD) is implemented using statistical software (e.g., Design Expert).

- For PNL, the factors and levels could be: Ethanol concentration (20%, 40%, 60%), Solid-liquid ratio (1:20, 1:25, 1:30), and Extraction time (40 h, 56 h, 72 h) [36].

- The model proposes 17 randomized experimental runs. The saponin extraction rate is the response value.

- Analyze the results to generate a predictive model and 3D response surface plots to identify the optimal interaction of factors and establish the final extraction process.

Protocol 2: Green Extraction Using Natural Deep Eutectic Solvents (NADES)

This protocol describes the synthesis of an optimized NADES and its application for the efficient extraction of steroidal saponins from Lilium lancifolium bulbs [31] [35].

3.2.1 Synthesis and Screening of NADES

- Preparation: Synthesize the NADES by combining Choline Chloride (HBA) and 1,2-Propylene Glycol (HBD) in a 1:1 molar ratio in a sealed flask [35]. Heat the mixture in a water bath at 80°C with continuous stirring until a clear, homogeneous liquid forms.

- Hydration: Add 40% (w/w) water to the synthesized NADES to reduce its viscosity and improve extraction efficiency [35].

- Stability Test: Store the prepared NADES at 4°C, protected from light, for an extended period (e.g., 100 days) to confirm stability before use [31].

3.2.2 NADES-Based Extraction

- Weigh 1 g of finely powdered Lilium lancifolium bulb.

- Use a solid-to-solvent ratio of 0.05 g/mL (e.g., 1 g sample with 20 mL of hydrated NADES) [35].

- Perform extraction using a suitable technique such as:

- Shaking-Assisted Extraction: Place the mixture on a shaker and extract for 89 minutes at 75°C [35].

- Ultrasound-Assisted Extraction (UAE): Subject the mixture to ultrasonication at a controlled temperature.

- Centrifuge the extract and collect the supernatant for analysis.

3.2.3 Quantitative and Qualitative Analysis

- Total Saponin Content: Use the vanillin glacial acetic acid-perchloric acid method. Measure absorbance at 560 nm and calculate the content against a diosgenin standard curve (e.g., y = 6.9174x + 0.0193, R² = 0.9992) [31].

- Component Identification: Analyze the NADES extract via UHPLC-MS/MS. The superior efficiency of NADES-15 was demonstrated by the tentative identification of 31 compounds, including all nine target steroidal saponins, compared to only 17 compounds and six saponins in the ethanol extract [31].

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for Saponin Extraction and Analysis

| Item | Function/Application | Example from Literature |

|---|---|---|

| Choline Chloride | A common Hydrogen Bond Acceptor (HBA) for synthesizing NADES. | Used in NADES-15 with citric acid [31] and with 1,2-propylene glycol for quinoa saponin extraction [35]. |

| 1,2-Propylene Glycol / Citric Acid | Hydrogen Bond Donors (HBD) for NADES formation, determining solvent properties. | 1,2-propylene glycol (HBD) with choline chloride [35]; Citric acid (HBD) with choline chloride [31]. |

| Ethanol (Aqueous Solutions) | Conventional extraction solvent; concentration optimization is critical. | Optimized at 40-60% for Panax leaf saponins [36]; used as a benchmark against NADES [31] [35]. |

| Authentic Saponin Standards | Essential for constructing calibration curves and definitive metabolite identification in UHPLC-MS/MS. | Calenduloside E (CE) and chikusetsusaponin IVa (ChIVa) for quantitative UPLC-MS/MS [13]. |

| Isotopically-Labelled Internal Standards | Added to samples to correct for matrix effects and losses during preparation in targeted quantification. | Ginsenoside Rh2 used as an internal standard for quantifying 20(S)-protopanaxadiol [32]. |

| Vanillin & Perchloric Acid | Key reagents for the colorimetric determination of total saponin content. | Used in vanillin-perchloric acid-sulfuric acid assay for Panax leaves [36] and for quinoa saponins [35]. |

Concluding Remarks for UHPLC-MS/MS Research

The integration of optimized sample preparation is the foundation of a robust UHPLC-MS/MS method for saponin quantification. The move towards green solvents like NADES, especially when coupled with assisted extraction techniques, provides a pathway to achieving higher yields, a more comprehensive metabolite profile, and reduced environmental impact. The protocols outlined here offer a validated, systematic approach to sample preparation, enabling researchers to generate highly reproducible and reliable quantitative data for their thesis research and beyond. By carefully selecting and optimizing the extraction process as detailed, scientists can ensure that the full potential of their UHPLC-MS/MS analysis is realized.

Chromatographic Column Selection and Mobile Phase Optimization

The development of robust, sensitive, and selective analytical methods for saponin quantification in plant materials remains a significant challenge in natural product research and drug development. This application note provides detailed protocols for chromatographic column selection and mobile phase optimization specifically tailored for UHPLC-MS/MS analysis of saponins. These compounds exhibit considerable structural diversity and often lack strong chromophores, making their separation and detection particularly demanding [37]. The methodologies presented herein support a broader thesis research endeavor focused on establishing a validated UHPLC-MS/MS method for precise saponin quantification in complex plant matrices.

Experimental Protocols

Column Selection Criteria and Stationary Phases

The selection of an appropriate chromatographic column is paramount for achieving optimal resolution of saponin compounds, which typically exist in plant extracts as complex mixtures of structurally similar analogs.

- Column Dimensions: For UHPLC-MS/MS applications, columns with dimensions of 100-150 mm in length × 2.1 mm internal diameter are widely recommended, packed with sub-2µm particles to achieve high efficiency separations with improved peak capacity [38].

- Stationary Phase Chemistry: The reversed-phase C18 chemistry remains the most extensively employed stationary phase for saponin separations. The Waters ACQUITY UPLC BEH C18 column (100 mm × 2.1 mm, 1.7 µm) has been successfully implemented for separating 31 saponins from Shizhu ginseng, demonstrating excellent performance under gradient elution conditions [38].

- Temperature Control: Maintaining consistent column temperature (typically 40°C) enhances chromatographic reproducibility by improving mobile phase viscosity and mass transfer properties [38].

Mobile Phase Composition and Optimization

Mobile phase optimization focuses on achieving baseline separation of target saponins while maintaining compatibility with MS detection systems.

- Organic Modifier Selection: Acetonitrile is generally preferred over methanol due to its lower viscosity and background signal in MS detection. Gradient elution programs typically initiate with 20% acetonitrile, gradually increasing to 30-35% over 10-30 minutes, effectively separating saponins of varying hydrophobicity [38].

- Acidic Additives: The incorporation of 0.1% formic acid in the aqueous mobile phase component enhances ionization efficiency in positive ESI mode by promoting protonation of saponin molecules [38]. This additive also improves peak symmetry by suppressing silanol interactions.

- Alternative Buffers: For negative ionization mode, 8 mM aqueous ammonium acetate serves as an effective mobile phase modifier, facilitating the formation of deprotonated molecular ions [M-H]- and chloride adducts [M+Cl]- which provide valuable structural information during MS/MS fragmentation studies [39].

Table 1: Optimized Mobile Phase Compositions for Saponin Analysis

| Application Focus | Organic Phase | Aqueous Phase | Gradient Program | Flow Rate | Citation |

|---|---|---|---|---|---|

| Ginseng Saponins (31 compounds) | Acetonitrile | 0.1% Formic Acid in Water | 20-30% ACN in 10 min, 30-35% in 30 min | 0.25 mL/min | [38] |

| Panax notoginseng Saponins | Acetonitrile | 8 mM Ammonium Acetate | Gradient elution over 50 min | Not specified | [39] |

| General Saponin Analysis | Acetonitrile | Water with acid or buffer additives | Optimized for specific saponin classes | 0.2-0.5 mL/min | [37] [34] |

Sample Preparation and Extraction Methodology

Proper sample preparation is critical for accurate saponin quantification and maintaining instrument performance.

- Extraction Solvent Optimization: 70% ethanol demonstrates superior extraction efficiency for most saponins when applied to powdered plant material (3g) using ultrasonic assistance at room temperature for 30 minutes [38]. This concentration effectively balances solubility with minimal co-extraction of non-target compounds.

- Ultrasonic vs. Reflux Extraction: Ultrasonic extraction at ambient temperature is preferred over reflux methods for preserving structural integrity of thermally labile saponins, particularly malonyl-ginsenosides which can degrade under elevated temperatures [38].

- Extract Processing: Following extraction, filtration and concentration under reduced pressure precedes reconstitution in 20% acetonitrile (10mL final volume) with subsequent filtration through 0.22µm membranes to eliminate particulate matter that could compromise UHPLC system performance [38].

MS/MS Detection Parameters

Mass spectrometric detection provides the specificity and sensitivity required for accurate saponin quantification in complex plant matrices.

- Ionization Mode Selection: Both positive and negative electrospray ionization (ESI) modes are employed, with negative mode often providing superior sensitivity and clearer structural information through characteristic fragmentation patterns [39].

- Source Parameters: Optimal MS parameters typically include capillary voltage of 2.9-3.0 kV, cone voltage of 50 V, source temperature of 105°C, and desolvation temperature of 350°C with nitrogen desolvation gas flow rates of 600 L/h [38] [39].

- Data Acquisition: Full scan MS data collection across 100-1200 m/z range in both ionization modes enables comprehensive saponin profiling, while MS/MS fragmentation through collision-induced dissociation (CID) provides structural elucidation capabilities [38].

Table 2: MS/MS Instrument Parameters for Saponin Analysis

| Parameter | Optimal Setting | Impact on Analysis | Application Note |

|---|---|---|---|

| Capillary Voltage | 2.9-3.0 kV | Influences ionization efficiency and signal intensity | Critical for negative ion mode [38] [39] |

| Cone Voltage | 50 V | Affects precursor ion transmission and fragmentation | Optimized for ginsenoside standards [38] |

| Ion Source Temperature | 105°C | Impacts desolvation process | Higher temperatures improve signal stability [38] |

| Desolvation Temperature | 350°C | Enhances solvent removal | Requires higher flow rates for saponins [38] |

| Desolvation Gas Flow | 600 L/h | Facilitates droplet disintegration and ion formation | Nitrogen typically used [38] |

| Collision Gas Pressure | 2.50 × 10⁻³ mbar (He) | Controls CID fragmentation patterns | Structural elucidation [38] [39] |

Visualized Workflows and Relationships

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Research Reagents and Materials for Saponin Analysis

| Reagent/Material | Specification | Function in Analysis | Application Example |

|---|---|---|---|

| UHPLC Column | C18, 100-150 × 2.1mm, 1.7-1.8µm | Stationary phase for compound separation | Waters ACQUITY UPLC BEH C18 [38] |

| Acetonitrile | HPLC-MS Grade | Organic mobile phase component | Gradient elution with 0.1% formic acid [38] |

| Formic Acid | LC-MS Grade (0.1%) | Mobile phase additive for positive ionization | Enhances [M+H]+ ion formation in ESI+ [38] |

| Ammonium Acetate | Analytical Grade (8mM) | Mobile phase buffer for negative ionization | Promotes [M-H]- and [M+Cl]- formation [39] |

| Ethanol | Analytical Grade (70%) | Extraction solvent for saponins | Ultrasonic extraction of plant material [38] |

| Reference Standards | Ginsenosides Rg1, Re, Rb1, etc. | Method calibration and compound identification | National Institute for Food and Drug Control [38] |

| Solid Phase Extraction | C18 or C8 cartridges | Extract clean-up and concentration | Removal of interfering compounds [37] |

This application note provides comprehensive protocols for chromatographic column selection and mobile phase optimization specifically designed for UHPLC-MS/MS analysis of plant saponins. The detailed methodologies cover the critical aspects of stationary phase chemistry, mobile phase composition, sample preparation, and MS detection parameters that collectively enable robust separation and accurate quantification of these challenging compounds. Implementation of these optimized conditions supports research objectives in natural product analysis, phytochemical characterization, and quality control of saponin-containing botanicals and herbal medicines.

The quantification of saponins in plant matrices using Ultra-High Performance Liquid Chromatography coupled with Tandem Mass Spectrometry (UHPLC-MS/MS) presents significant analytical challenges due to the structural diversity, wide polarity range, and often low abundance of these compounds within complex biological samples. The sensitivity, accuracy, and reproducibility of the analysis are profoundly influenced by the mass spectrometric parameters, particularly the ionization mode and source conditions. This document provides detailed application notes and protocols for optimizing these critical parameters, framed within the context of developing a robust UHPLC-MS/MS method for saponin quantification in plant research, supporting drug development endeavors.

Ionization Mode Selection for Saponin Analysis

The first critical step in method development is selecting the appropriate ionization mode. Saponins, being glycosides, can be effectively ionized in both positive and negative modes, but the choice significantly impacts the spectrum and quality of the data.

Positive Ionization Mode (+ESI): In this mode, saponins typically form adducts with alkali metal ions such as sodium or potassium, resulting in prominent [M+Na]⁺ or [M+K]⁺ ions [38] [40]. This is a highly reliable and sensitive mode for many ginsenosides and triterpenoid saponins. The formation of these stable adducts provides a consistent target for Selected Reaction Monitoring (SRM) transitions, which is crucial for quantitative work.

Negative Ionization Mode (-ESI): Saponins can also be efficiently analyzed by detecting deprotonated [M-H]⁻ ions [41] [40]. This mode is often preferred for saponins with glucuronic acid moieties or other acidic functional groups, as it facilitates clean and sensitive detection. The affinity for negative mode can vary with the saponin's specific structure.

For comprehensive screening and quantification of diverse saponin profiles, it is highly recommended to acquire data in both positive and negative modes, as demonstrated in the separation of 31 saponins from Shizhu ginseng [38]. The table below summarizes the characteristics of each ionization mode.

Table 1: Comparison of Ionization Modes for Saponin Analysis

| Ionization Mode | Typical Ion Formed | Advantages | Common Saponin Applications |

|---|---|---|---|

| Electrospray Positive (+ESI) | [M+Na]⁺, [M+K]⁺ | Stable, reproducible adducts; High sensitivity for many ginsenosides | Ginsenosides (Rg1, Re, Rb1, etc.) [38] |

| Electrospray Negative (-ESI) | [M-H]⁻ | Ideal for acidic saponins; Clean spectra | Saponins with glucuronic acid; Steroidal saponins [41] |

Optimization of ESI Source Conditions

The electrospray ionization source conditions are pivotal for achieving stable and efficient ion generation, which directly affects signal intensity and method robustness. The following parameters must be systematically optimized for a specific saponin-plant matrix combination.