A Comprehensive GC-MS Protocol for Plant Essential Oil Analysis: From Sample Preparation to Bioactivity Correlation

This article provides a detailed guide for researchers and drug development professionals on the Gas Chromatography-Mass Spectrometry (GC-MS) analysis of plant essential oils.

A Comprehensive GC-MS Protocol for Plant Essential Oil Analysis: From Sample Preparation to Bioactivity Correlation

Abstract

This article provides a detailed guide for researchers and drug development professionals on the Gas Chromatography-Mass Spectrometry (GC-MS) analysis of plant essential oils. It covers the foundational principles of essential oil chemistry and their therapeutic relevance, a step-by-step methodological protocol from sample preparation to data acquisition, common troubleshooting and optimization strategies for complex analyses, and rigorous validation techniques to ensure data accuracy and reproducibility. By integrating chemical profiling with bioactivity assessment, this resource supports the reliable characterization of essential oils for pharmaceutical and biomedical applications, addressing key challenges in natural product research.

Unlocking the Chemistry of Plant Essential Oils: Principles and Therapeutic Potential

Essential Oils as Complex Mixtures of Bioactive Terpenes and Phenylpropanoids

Essential oils (EOs) are complex, volatile, and lipophilic mixtures of odoriferous substances synthesized by aromatic plants [1]. They are defined as products obtained from plant raw materials primarily through steam or hydrodistillation, separating the "essential" or volatile constituents from the non-volatile plant material [1] [2]. These oils typically contain 20-60 components at different concentrations, with two or three major constituents often present in large proportions (20-70%) that frequently dictate the oil's biological properties [1]. The chemical composition of essential oils derives mainly from two biosynthetic groups: terpenes (monoterpenes, sesquiterpenes, and their derivatives) and phenylpropanoids (aromatic compounds with a propene tail) [1] [2]. Understanding this complex chemistry is fundamental to researching their diverse pharmacological activities, which include antimicrobial, anti-inflammatory, antioxidant, and anticancer effects [1] [3] [4]. The analysis of these complex mixtures relies heavily on Gas Chromatography-Mass Spectrometry (GC-MS), which provides both qualitative identification and quantitative determination of their volatile constituents [5].

Experimental Protocols for GC-MS Analysis of Essential Oils

Sample Preparation and Extraction

Hydrodistillation Protocol using Clevenger Apparatus:

- Plant Material Preparation: Use 50 g of fresh plant material (leaves and stems). For consistent results, ensure plant material is sourced from verified suppliers and authenticated [3].

- Distillation Setup: Transfer plant material to a Clevenger apparatus flask. Add sufficient distilled water to cover plant material (typically 500 mL for 50 g sample) [3].

- Distillation Parameters: Conduct hydrodistillation for 1.5 hours. Monitor temperature to maintain steady boiling without superheating [3].

- Oil Collection: Following distillation, separate the essential oil layer from the hydrosol. Transfer essential oil to amber vials using a Pasteur pipette.

- Storage: Store extracted oils at 4°C until analysis to prevent volatility losses and chemical degradation [3].

Note on Extraction Variations: Yield and composition can vary significantly based on plant material, geographic origin, harvesting conditions, and extraction techniques [6]. For citrus oils, mechanical pressing of rinds is an acceptable alternative method per international standards [2].

GC-MS Instrumental Analysis Protocol

Equipment and Materials:

- GC-MS system (e.g., Shimadzu GCMS-QP2010)

- Chromatographic column: Rtx-5MS fused silica capillary column (30 m × 0.25 mm internal diameter × 0.25 µm film thickness)

- Carrier gas: Helium (purity ≥ 99.999%)

- Sample vials and syringes for injection

GC-MS Operational Parameters [3]:

- Injector temperature: 250°C

- Injection mode: Split mode with 1:15 split ratio

- Carrier gas flow rate: 1.41 mL/min (constant flow)

- Oven temperature program:

- Initial temperature: 45°C held for 2 minutes

- Ramp rate: 5°C per minute to 300°C

- Final temperature: 300°C held for 5 minutes

- Total run time: 59 minutes

- Sample preparation: Dilute essential oil to 1% (v/v) in appropriate solvent (e.g., hexane or methanol)

Mass Spectrometer Conditions [3]:

- Ionization mode: Electron Impact (EI)

- Ionization energy: 70 eV

- Ion source temperature: 200°C

- Interface temperature: 250°C

- Mass scan range: 40-500 m/z

- Solvent cut time: 3-5 minutes

Data Analysis and Compound Identification

Qualitative Analysis [5]:

- Peak Identification: Identify analytes by comparing mass spectra with reference libraries (e.g., NIST, Wiley). Match fragmentation patterns to known compound spectra.

- Retention Index Calculation: Calculate arithmetic indices using n-alkane series under identical chromatographic conditions.

- Compound Verification: Compare retention times and mass spectra with authentic standards when available.

Quantitative Analysis [5]:

- Peak Integration: Integrate peak areas using the instrument's software. For overlapping peaks, use appropriate integration algorithms to accurately divide shared areas.

- Calibration: Establish calibration curves using internal standards to account for injection volume variations and matrix effects.

- Concentration Calculation: Determine component concentrations using response factors relative to internal standards. The molar response factor (r) for a component is defined as: r = peak area / moles of compound injected.

Chemical Composition of Essential Oils

Biosynthetic Pathways

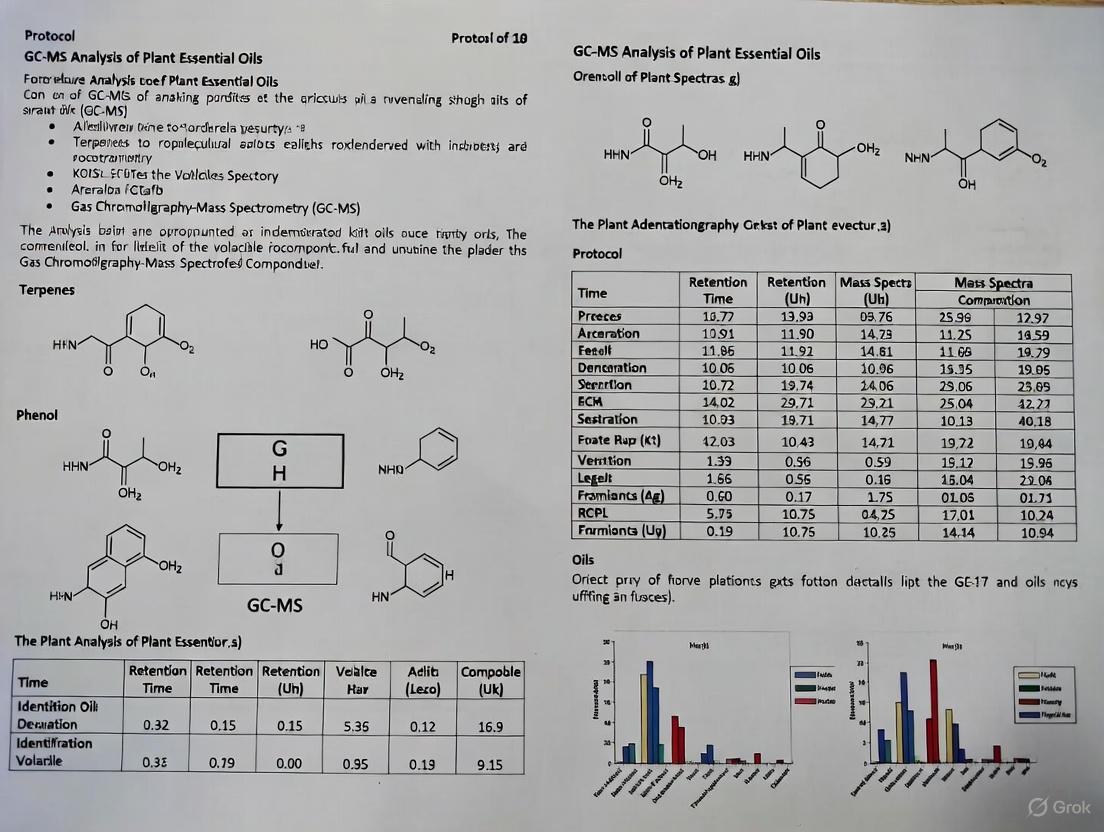

The following diagram illustrates the major biosynthetic pathways responsible for the production of essential oil components:

Major Chemical Classes in Essential Oils

Table 1: Major Chemical Classes Found in Essential Oils

| Chemical Class | Carbon Atoms | Biosynthetic Origin | Representative Compounds | Example Sources |

|---|---|---|---|---|

| Monoterpenes | C10H16 | MEP Pathway | Limonene, Pinene, Myrcene | Citrus spp., Pine |

| Oxygenated Monoterpenes | C10H16O | MEP Pathway | 1,8-Cineole, Linalool, Menthol | Eucalyptus globulus, Lavender, Mint |

| Sesquiterpenes | C15H24 | MVA Pathway | Caryophyllene, Farnesene, Chamazulene | Chamomile, Cedarwood |

| Oxygenated Sesquiterpenes | C15H24O | MVA Pathway | Bisabolol, Spathulenol, Caryophyllene oxide | Artemisia spp., Ylang-ylang |

| Phenylpropanoids | C6-C3 | Shikimate Pathway | Eugenol, Cinnamaldehyde, Anethole | Clove, Cinnamon, Anise |

Quantitative Composition of Selected Essential Oils

Table 2: Quantitative Composition of Essential Oils from Various Medicinal Plants

| Plant Species | Major Compounds | Relative Content (%) | Extraction Yield (% v/w) | Notable Minor Compounds |

|---|---|---|---|---|

| Artemisia absinthium | α-Thujone | 29.02 | 1.2 | Chamazulene (6.92%), (-)-4-Terpineol (3.68%) |

| Camphor | 24.34 | |||

| Eucalyptus globulus | Spathulenol | 15.00 | 3.0 | Caryophyllene oxide (7.67%) |

| Syzygium aromaticum | Eugenol | 54.96 | 7.5 | Not specified |

| Mentha canadensis | Pulegone | Not specified | Not specified | Menthone, Piperitenone oxide |

| Plectranthus amboinicus | Thymol | Not specified | Not specified | Citronellol, Levomenthol |

Bioactivity Assessment Protocols

Cytotoxicity Assessment (MTT Assay)

Protocol for Evaluating Cytotoxicity in Vero Cell Lines [3]:

- Cell Culture: Maintain Vero cell lines in appropriate growth medium at 37°C in a 5% CO₂ atmosphere.

- Sample Preparation: Prepare essential oils at initial concentration of 200 mg/mL. Perform two-fold serial dilutions in culture medium.

- Treatment: Apply diluted essential oils to pre-cultured Vero cell lines. Incubate for 24 hours at 37°C.

- Viability Assessment: Remove growth medium and wash with phosphate-buffered saline (PBS, pH 7.2 ± 0.2) containing 0.05% Tween to remove dead cells.

- MTT Staining: Add 0.5% MTT stain (25 µL per well) to remaining viable cells. Incubate for 3-4 hours at 37°C.

- Solubilization: Solubilize formed formazan crystals with 0.05 mL dimethyl sulfoxide (DMSO) per well. Shake for 30 minutes.

- Measurement: Read optical densities at appropriate wavelength using ELISA plate reader.

- Calculation: Determine IC₅₀ values using appropriate software (e.g., Master-plex-2010). Calculate cell viability percentage using formula:

Cell Viability (%) = (OD of Treated Cells / OD of Untreated Cells) × 100

Antimicrobial Activity Assessment

Disc Diffusion Method Protocol [6]:

- Test Microorganisms: Use standard reference strains including Escherichia coli (ATCC 25922), Pseudomonas aeruginosa (ATCC 27853), Staphylococcus aureus (ATCC 25923), Candida albicans (ATCC 10231), and Bacillus subtilis (ATCC 6633).

- Inoculum Preparation: Adjust microbial suspensions to 0.5 McFarland standard.

- Inoculation: Evenly spread inoculum on appropriate agar plates.

- Disc Preparation: Impregnate sterile filter paper discs with known concentrations of essential oils.

- Incubation: Apply discs to inoculated agar plates. Incubate at appropriate temperatures for 18-24 hours.

- Measurement: Measure inhibition zones (including disc diameter) in millimeters using calipers.

Antioxidant Activity Assessment

DPPH Radical Scavenging Assay Protocol [3]:

- Solution Preparation: Prepare 0.1 mM DPPH solution in methanol.

- Sample Preparation: Prepare serial dilutions of essential oils in appropriate solvent.

- Reaction: Mix sample solutions with DPPH solution. Incubate in dark for 30 minutes.

- Measurement: Measure absorbance at 517 nm against blank.

- Calculation: Calculate percentage inhibition using formula:

Scavenging Activity (%) = [(A₀ - A₁) / A₀] × 100

Where A₀ is absorbance of control and A₁ is absorbance of sample.

- IC₅₀ Determination: Determine concentration providing 50% inhibition from dose-response curve.

Experimental Workflow Integration

The following diagram illustrates the integrated workflow for essential oil analysis from extraction to bioactivity assessment:

Research Reagent Solutions and Essential Materials

Table 3: Essential Research Reagents and Materials for Essential Oil Analysis

| Category | Specific Items | Function/Application | Technical Specifications |

|---|---|---|---|

| Extraction Equipment | Clevenger Apparatus | Hydrodistillation of plant material | Standard 2L capacity with essential oil receiver |

| MS Medium | Plant tissue culture for standardized material | Ready media from commercial suppliers (e.g., Caisson - USA) | |

| Chromatographic Supplies | Rtx-5MS Capillary Column | GC-MS separation of volatile compounds | 30 m × 0.25 mm ID × 0.25 µm film thickness |

| Helium Carrier Gas | Mobile phase for GC-MS | Ultra-high purity (≥99.999%) | |

| n-Alkane Standards | Retention index calculation | C8-C40 series for calibration | |

| Cell Culture Reagents | Vero Cell Line (ATCC CCL-81) | Cytotoxicity assessment | African green monkey kidney cells |

| MTT Reagent | Cell viability assessment | 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide | |

| DMEM Growth Medium | Cell culture maintenance | With 10% FBS and antibiotics | |

| Microbiological Materials | Reference Microbial Strains | Antimicrobial activity testing | ATCC strains: E. coli 25922, S. aureus 25923, C. albicans 10231, etc. |

| Mueller-Hinton Agar | Antimicrobial susceptibility testing | Standardized medium for disc diffusion | |

| Antioxidant Assay Reagents | DPPH (2,2-diphenyl-1-picrylhydrazyl) | Free radical scavenging assessment | 0.1 mM solution in methanol, prepared fresh |

| Data Analysis Software | NIST Mass Spectral Library | Compound identification | 2023 or newer version with essential oil spectra |

| Master-plex-2010 | IC₅₀ calculation and data analysis | Version 2.0.0.77 or compatible |

Core Principles of Gas Chromatography-Mass Spectrometry (GC-MS) for Volatile Analysis

Gas Chromatography-Mass Spectrometry (GC-MS) stands as a cornerstone analytical technique for the separation, identification, and quantification of volatile and semi-volatile organic compounds. Its application is particularly pivotal in the analysis of plant essential oils, which are complex mixtures of dozens, sometimes hundreds, of constituent chemicals. The power of GC-MS lies in its two-dimensional separation: the gas chromatography (GC) component separates the complex mixture into individual compounds, while the mass spectrometry (MS) component provides structural information for the unambiguous identification of each separated analyte. This makes it an indispensable tool for researchers, scientists, and drug development professionals seeking to characterize natural products, authenticate raw materials, and discover bioactive compounds for therapeutic applications.

Core Principles and Instrumentation

The fundamental principle of GC-MS involves the separation of compounds based on their differential partitioning between a mobile gas phase and a stationary phase, followed by ionization and mass analysis of the separated components.

The Gas Chromatograph

The GC system is designed to vaporize a sample and transport it through a long, narrow column via an inert carrier gas. The core components and their functions are detailed in the "Research Reagent Solutions" table in Section 5. Separation occurs because each compound in the mixture interacts differently with the stationary phase coating the inner wall of the column, causing them to elute at different times, known as retention times. Precise temperature control of the column oven is critical; separation is often achieved using a temperature ramp, where the oven temperature is systematically increased to elute compounds with a wide range of volatilities efficiently [7].

The Mass Spectrometer

As each compound elutes from the GC column, it enters the mass spectrometer, which operates under high vacuum. Here, molecules are ionized, most commonly by Electron Ionization (EI) at 70 eV, which bombards them with high-energy electrons, resulting in the formation of positively charged molecular and fragment ions [7] [8]. These ions are then separated based on their mass-to-charge ratio (m/z) by a mass analyzer (e.g., quadrupole or ion trap). The detector records the abundance of ions at each m/z value, generating a mass spectrum—a unique molecular "fingerprint" that can be compared against extensive reference libraries, such as the NIST database, for identification [7].

Detailed Experimental Protocol for Essential Oil Analysis

The following protocol, adapted from a published methodology for analyzing Salvia lanigera essential oil, provides a robust framework for the GC-MS analysis of plant volatiles [8].

Sample Preparation

- Essential Oil Extraction: Fresh or dried aerial parts of the plant material (e.g., 500 g) are subjected to hydrodistillation using a Clevenger apparatus for a period of 3 hours. The obtained essential oil layer is then dried over anhydrous sodium sulfate (Na₂SO₄) to remove traces of water and stored in amber glass vials at 4°C until analysis [8].

- Sample Dilution: Prior to GC-MS injection, the essential oil must be properly diluted with a suitable volatile solvent to fall within the dynamic range of the detector. A common dilution is 1:20 (v:v) in n-hexane [7].

Instrumental Configuration and Parameters

The quantitative parameters for instrument setup are consolidated in the table below for easy reference.

Table 1: Standardized GC-MS Operating Conditions for Essential Oil Analysis [7]

| Parameter | Specification |

|---|---|

| GC Instrument | Varian Saturn 2100T (or equivalent) |

| Column | VF-5ms (30 m × 0.25 mm × 0.25 µm film thickness) |

| Carrier Gas | Helium (He 6.0) |

| Flow Rate | 1 mL/min |

| Injection Volume | 1 µL |

| Injection Mode | Split (split ratio 1:20) |

| Injector Temperature | 230 °C |

| Oven Temperature Program | Hold at 40 °C for 4 min; Ramp to 150 °C at 5 °C/min; Hold at 150 °C for 13 min; Ramp to 200 °C at 10 °C/min; Hold at 200 °C for 15 min. |

| Total Run Time | 59 min |

| Ionization Mode | Electron Ionization (EI) |

| Ionization Energy | 70 eV |

| Mass Scan Range | 50 - 650 m/z |

| Detector Temperature | 150 °C |

Data Analysis and Compound Identification

- Peak Identification: Constituents are identified by comparing the mass spectrum of each chromatographic peak with spectra stored in commercial libraries (e.g., NIST). The identification is further corroborated by comparing the calculated Kovats retention index of the compound with literature values [8].

- Quantification: The relative percentage of each identified compound is typically computed based on the peak area relative to the total integrated area of all peaks in the chromatogram (area normalization method without correction factors).

Advanced Applications and Comparative Techniques

GC-MS is routinely used to characterize the complex chemical profiles of medicinal plants. For instance, a study on Libyan Salvia lanigera identified 24 compounds representing 99.33% of the total oil, with major constituents being 1,8-cineole (27.28%), camphor (25.82%), α-pinene (7.71%), and α-terpineol (7.67%) [8]. This chemical knowledge is foundational for linking composition to biological activity, such as the observed antioxidant, anti-acetylcholinesterase, and anti-diabetic properties of the extract [8].

Emerging techniques like Gas Chromatography-Ion Mobility Spectrometry (GC-IMS) are gaining attention. A 2025 comparative study highlighted that GC-IMS offers approximately ten times higher sensitivity than GC-MS for certain volatile organic compounds (VOCs), achieving limits of detection in the picogram per tube range. However, GC-MS maintains a significant advantage with a broader linear dynamic range (up to three orders of magnitude) and the unparalleled ability to identify unknown compounds via extensive mass spectral libraries [9]. The integration of both detectors in a TD-GC-MS-IMS system leverages the strengths of each, providing high-sensitivity detection and definitive identification, which is particularly valuable in clinical and environmental diagnostics [9].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Research Reagent Solutions for GC-MS Analysis of Essential Oils

| Reagent / Material | Function and Application in GC-MS Protocol |

|---|---|

| n-Hexane | A volatile solvent used for proper dilution of concentrated essential oil samples prior to injection to prevent column and detector overload [7]. |

| Anhydrous Sodium Sulfate (Na₂SO₄) | Used to dry the extracted essential oil by removing residual water, which can damage the GC column and interfere with analysis [8]. |

| Clevenger Apparatus | A specialized glassware setup for the hydrodistillation of plant material to isolate essential oils for subsequent analysis [8]. |

| Helium (He 6.0) | Serves as the high-purity carrier gas, responsible for moving the vaporized sample through the GC column [7]. |

| HP-5ms / VF-5ms Capillary Column | A (5%-phenyl)-methylpolysiloxane non-polar stationary phase column, which is the industry standard for separating complex volatile mixtures like essential oils [7] [8]. |

| NIST Mass Spectral Library | A comprehensive database of reference mass spectra used as the primary tool for identifying unknown compounds by comparing their spectral fingerprint [7] [8]. |

| Alkane Standard Mixture (C6-C26) | A calibrated mixture of n-alkanes used to calculate the Kovats Retention Index for each compound, providing a second, reliable parameter for confirming compound identity [8]. |

Workflow and Data Interpretation

The following diagram illustrates the logical workflow for a GC-MS analysis, from sample preparation to final reporting.

GC-MS Analysis Workflow for Essential Oils

The resulting data is typically presented as a total ion chromatogram (TIC), where each peak corresponds to a separated compound. The mass spectrum for each peak is interpreted by the instrument's software and matched against the reference library, providing a list of tentative identities along with a confidence score (e.g., match factor). The final report includes the compound name, its retention time, and its relative percentage abundance in the oil, forming the basis for further chemotaxonomic or bioactivity studies.

Key Bioactive Compounds in Common Medicinal Plants and Their Reported Activities

Medicinal plants have served as a cornerstone for therapeutic interventions throughout human history, providing a rich source of structurally diverse bioactive compounds. In contemporary drug discovery, these natural products continue to offer valuable lead compounds and therapeutic agents for treating various ailments, from infectious diseases to chronic conditions [10]. The growing challenge of antimicrobial resistance, which accounts for millions of fatalities annually with projections indicating a rise to 10 million deaths per year by 2050, has further intensified research into plant-derived antimicrobial alternatives [11]. This application note explores the key bioactive compounds from common medicinal plants, their reported biological activities, and provides detailed experimental protocols for their analysis via GC-MS, framed within broader research on plant essential oils.

Bioactive Compounds and Biological Activities

Medicinal plants produce numerous secondary metabolites categorized as bioactive compounds, including alkaloids, steroids, tannins, phenolic compounds, and flavonoids, which elicit specific physiological effects on the body [12]. These compounds offer notable therapeutic advantages including safety, cost-effectiveness, efficacy, and accessibility [12]. The table below summarizes key bioactive compounds from selected medicinal plants and their demonstrated biological activities.

Table 1: Key Bioactive Compounds in Common Medicinal Plants and Their Reported Activities

| Medicinal Plant | Bioactive Compound | Reported Biological Activities | Citation |

|---|---|---|---|

| Artemisia annua (Sweet wormwood) | Artemisinin | Antimalarial, effective against drug-resistant malaria | [11] [10] |

| Salvia lanigera (Wooly Sage) | 1,8-Cineole, Camphor, α-Pinene | Antioxidant, anti-acetylcholinesterase, antidiabetic | [8] |

| Mentha piperita (Peppermint) | Menthol, Menthone, Menthyl acetate | Antibacterial, antioxidant, antidiabetic, dermatoprotective, neuroprotective | [13] |

| Dendranthema indicum var. aromaticum (Aromatic Chrysanthemum) | α-Thujone, β-Thujone, cis-Sabinol, Sabinyl acetate | Antimicrobial, antioxidant, treatment of colds and headaches, mosquito repellent | [14] |

| Tamarindus indica (Tamarind) | 5-Hydroxymethylfurfural, 3-O-Methyl-d-glucose | Antibacterial, antifungal, antitubercular, anticancer, antioxidant | [15] |

| Lavandula spp. (Lavender) | Linalool, Linalyl acetate, Camphor | Antifungal, antibacterial, antioxidant, insect repellent, aromatherapy | [16] |

| Curcuma longa (Turmeric) | Curcumin | Anti-inflammatory, antioxidant, treatment of diarrhea and dysentery | [11] |

Experimental Protocols for GC-MS Analysis of Plant Essential Oils

Gas Chromatography-Mass Spectrometry (GC-MS) is a pivotal analytical technique for separating, identifying, and quantifying volatile compounds in plant essential oils. The following section outlines detailed protocols for essential oil extraction and GC-MS analysis.

Essential Oil Extraction Protocols

A. Hydrodistillation Method (Clevenger Apparatus)

- Apparatus: Clevenger-type apparatus.

- Sample Preparation: Use fresh or dried aerial parts of the plant material (e.g., 500 g of Salvia lanigera). Gently crush or chop to increase surface area [8].

- Procedure:

- Place the plant material in a round-bottom flask and add distilled water (typically 1:10 to 1:15 plant-to-water ratio).

- Assemble the Clevenger apparatus and heat the flask using an isomantle or heating mantle.

- Maintain a steady boil for 3-4 hours. The essential oil and water vapor condense in the condenser.

- The condensed essential oil, being immiscible and less dense than water, gets collected in the graduated side arm.

- Separate the oil layer from the hydrosol, dry over anhydrous sodium sulfate (Na₂SO₄) to remove traces of water.

- Filter the dried oil and store in sealed, amber glass vials at 4°C until analysis [8].

B. Microwave-Assisted Extraction (MAE)

- Apparatus: Microwave reactor system.

- Advantages: Superior performance in extraction yields, reduced solvent consumption, and shorter extraction time compared to conventional methods [14].

- Sample Preparation: Grind dried plant material to a uniform powder.

- Procedure:

- Place the powdered plant material in a microwave-compatible vessel.

- Add a suitable solvent (e.g., hexane or water) in a specified ratio.

- Set the microwave parameters (power, temperature, and time) optimized for the specific plant material. For Dendranthema indicum var. aromaticum, specific conditions were applied but not detailed in the source [14].

- After irradiation, cool the extract and filter.

- Remove the solvent under reduced pressure using a rotary evaporator to obtain the essential oil.

- Store as per hydrodistillation method.

GC-MS Analysis Protocol

A. Sample Preparation for GC-MS

- Liquid Injection (for extracted essential oils): Dilute the essential oil in a suitable volatile organic solvent (e.g., n-hexane, dichloromethane) to an approximate concentration of 1-10 mg/mL. Filter through a 0.22 μm syringe filter if necessary [8] [13].

- Headspace (HS) Sampling (for direct analysis of volatiles): Place a small amount of solid plant material or diluted essential oil (e.g., 1:20 v/v in solvent) in a headspace vial. Seal the vial with a PTFE/silicone septum cap [14] [16].

B. Instrumental Conditions (General Guidelines)

The following parameters, compiled from multiple studies, provide a robust starting point for GC-MS analysis of plant essential oils [14] [8] [16].

Table 2: Typical GC-MS Instrumental Conditions for Essential Oil Analysis

| Parameter | Specification | Alternative/Note |

|---|---|---|

| GC System | Agilent 8890/5977B MSD or equivalent | |

| Column | HP-5MS (30 m x 0.25 mm i.d., 0.25 μm) | Medium-polarity standard column. For broader profiling, also use a polar column (e.g., HP-INNOWAX) [14] [8]. |

| Injector Temperature | 230-250 °C | |

| Injection Mode | Split (ratio 1:10 to 1:50) | Splitless mode can be used for trace analysis. |

| Injection Volume | 0.5 - 1.0 μL | |

| Carrier Gas | Helium | |

| Flow Rate | 1.0 - 2.0 mL/min (constant flow) | |

| Oven Temperature Program | Initial: 50-60 °C (hold 1-2 min) | Example from Salvia lanigera: 50°C (2 min) to 200°C @ 5°C/min, then to 280°C @ 10°C/min (hold 7 min) [8]. |

| Ramp 1: 3-5 °C/min to 200-220 °C | ||

| Ramp 2: 5-10 °C/min to 240-280 °C (hold 3-7 min) | ||

| MS Transfer Line Temp. | 250-280 °C | |

| Ion Source Temperature | 230 °C | |

| Ionization Mode | Electron Impact (EI) | |

| Ionization Energy | 70 eV | |

| Mass Scan Range | 40-500 m/z |

Compound Identification and Data Analysis

- Peak Identification: Identify compounds by comparing the mass spectra of unknown peaks with reference spectra in standard libraries (e.g., NIST, Wiley). A similarity index (SI) of >85-90% is often considered a good match [8] [15].

- Retention Index (RI) Calculation: Calculate the Kovats Retention Index (RI) for each compound by analyzing a homologous series of n-alkanes (e.g., C6-C26) under the same GC conditions. Compare the calculated RI values with literature RI values for the same/similar stationary phase to confirm identification [8].

- Quantification: Report the relative percentage amount of each compound based on the peak area relative to the total integrated area from the chromatogram (area normalization method without correction factors) [14].

Biosynthetic Pathways of Key Bioactive Compounds

The bioactive compounds found in essential oils, such as monoterpenes and sesquiterpenes, are synthesized in plants through distinct metabolic pathways. The following diagram illustrates the logical workflow and relationship between the major biosynthetic pathways and the resulting compound classes.

The Scientist's Toolkit: Key Research Reagent Solutions

This section details essential reagents, materials, and instruments required for conducting research on bioactive compounds from medicinal plants, particularly for extraction and GC-MS analysis.

Table 3: Essential Research Reagents and Materials for Plant Bioactive Compound Analysis

| Reagent/Material | Function/Application | Example Specification/Citation |

|---|---|---|

| Anhydrous Sodium Sulfate (Na₂SO₄) | Drying agent for removing traces of water from extracted essential oils. | Analytical Grade [8] |

| Methanol, Ethanol, n-Hexane | Solvents for extraction and dilution of samples for GC-MS analysis. | HPLC or Analytical Grade [8] [15] |

| DPPH (2,2-Diphenyl-1-picrylhydrazyl) | Free radical reagent for evaluating antioxidant activity via radical scavenging assays. | Purity ≥ 90% [8] [15] |

| ABTS (2,2'-Azino-bis-3-ethylbenzothiazoline-6-sulfonic acid) | Reagent for determining antioxidant capacity through electron transfer mechanism. | For biochemistry [8] |

| Mueller Hinton Broth | Culture medium for antibacterial susceptibility testing, specifically for Minimum Inhibitory Concentration (MIC) determination. | Standard formulation for antibiotic testing [15] |

| NIST Mass Spectral Library | Reference database for identifying unknown compounds by comparing their mass spectra with known standards. | NIST MS 2.0 or later [8] [15] |

| n-Alkane Standard Solution (C6-C26) | Used for calculating Kovats Retention Index (RI) for precise compound identification in GC-MS. | Certified Reference Material [8] |

| GC-MS Capillary Columns | For separation of volatile compounds. HP-5MS (non-polar) and HP-INNOWAX (polar) provide complementary data. | 30m length, 0.25mm i.d., 0.25μm film thickness [14] [8] |

The analysis of bioactive compounds in medicinal plants via GC-MS provides an invaluable protocol for identifying and characterizing potential therapeutic agents. The detailed methodologies outlined in this application note—from optimized extraction techniques to rigorous GC-MS parameters and compound verification steps—offer researchers a standardized framework for reproducible analysis. As the field advances, the integration of traditional knowledge with modern analytical techniques like GC-MS and metabolomics continues to be a powerful strategy for drug discovery and development, addressing pressing global health challenges such as antimicrobial resistance and chronic diseases [11] [12]. Future perspectives point toward the increasing use of interdisciplinary approaches combining genomics, metabolomics, and nanotechnology to further unlock the potential of medicinal plants [12].

The Critical Link Between Chemical Composition and Bioactivity (Antimicrobial, Cytotoxic, Anti-inflammatory)

The therapeutic application of plant essential oils (EOs) represents a cornerstone of traditional and modern phytotherapy. The efficacy of these complex natural mixtures is fundamentally governed by their unique chemical profiles, which determine a spectrum of bioactivities including antimicrobial, cytotoxic, and anti-inflammatory effects [17] [18]. Advances in analytical technologies, particularly Gas Chromatography-Mass Spectrometry (GC-MS), have enabled researchers to precisely characterize these volatile compounds and establish critical structure-activity relationships [19] [20]. This Application Note provides a consolidated framework for the GC-MS analysis of plant essential oils and details standardized protocols for evaluating their key biological activities, thereby supporting drug discovery and natural product development.

Chemical Composition of Essential Oils and Correlating Bioactivities

Essential oils are complex mixtures of volatile compounds, primarily terpenes, terpenoids, and phenylpropanoids. Their bioactivity is directly influenced by the identity, concentration, and synergistic interactions of these constituents [21] [18].

Table 1: Major Bioactive Compounds in Essential Oils and Their Documented Effects

| Essential Oil (Plant Source) | Major Identified Compounds (GC-MS) | Documented Bioactivity | Key Findings |

|---|---|---|---|

| Thyme (Thymus vulgaris) [19] | Thymol (17.4%), γ-Terpinene (15.2%), Eucalyptol (24.3%) | Antimicrobial | Showed the maximum zone of inhibition against S. aureus, E. coli, and C. albicans. [19] |

| Eucalyptus (Eucalyptus globulus) [20] | Eucalyptol (62.32%), p-Cymene (8.11%), Globulol (5.9%) | Antioxidant, Antibacterial | Fraction F3 showed highest antioxidant activity (DPPH IC₅₀ = 3.329 mg/mL). EO showed antibacterial activity against S. aureus and E. coli. [20] |

| Oregano (Origanum vulgare) [21] | Carvacrol, Thymol | Antimicrobial, Antibiofilm | Potent activity against MSSA, MRSA, and E. coli. Significantly inhibited MSSA biofilm formation. [21] |

| Basil (Ocimum basilicum) [17] | Linalool (52.1%), Linalyl Acetate (19.1%) | Antioxidant, Anticancer | Ethanolic extract and EO showed moderate antioxidant and antimicrobial activities. EO showed anticancer activity (LD₅₀ 300–1000 μg/mL). [17] |

| Rosemary (Rosmarinus officinalis) [21] | 1,8-Cineole, Camphor | Antimicrobial | Showed potent activity against MSSA and MRSA. [21] |

| Tea Tree (Melaleuca alternifolia) [21] | Terpinen-4-ol | Antimicrobial, Antibiofilm | Exhibited the broadest spectrum of antimicrobial activity against all tested pathogens, including MRSA and P. aeruginosa. [21] |

The bioactivity of an essential oil is not merely the sum of its parts. Synergistic interactions between major and minor components can enhance efficacy. For instance, the antimicrobial power of thyme oil is largely attributed to its high phenolic content (thymol), which is known to disrupt microbial cell membranes [19]. Conversely, Eucalyptus oil's primary component, eucalyptol, is associated with both antioxidant and anti-inflammatory properties [20] [18]. The data in Table 1 underscores that oils rich in phenolic compounds (e.g., thyme, oregano) often exhibit strong antimicrobial effects, while the overall bioactivity profile is determined by the complex interplay of the entire chemical ensemble.

Experimental Protocols

This section outlines standardized methodologies for the analysis of essential oils, from chemical characterization to bioactivity assessment.

Protocol 1: GC-MS Analysis of Essential Oil Composition

Principle: GC-MS separates the volatile components of an essential oil, which are then identified by their mass spectra.

Workflow:

Detailed Procedure:

- Essential Oil Extraction: Hydrodistillation is performed for 3-6 hours using a Clevenger-type apparatus. Typically, 500 g of dried plant material is distilled with 750 mL of water until exhaustion. The obtained essential oil is dehydrated and stored in sealed vials at -4 °C in the dark [19] [20].

- GC-MS Analysis:

- Instrument: Gas Chromatograph coupled with a Mass Spectrometer detector.

- Column: Non-polar to mid-polar capillary column (e.g., HP-5MS, 30 m x 0.25 mm i.d., 0.25 µm film thickness).

- Oven Program: Initial temperature 50-60°C (hold 2-5 min), ramp to 220-280°C at 3-5°C/min, final hold for 5-10 min.

- Carrier Gas: Helium at a constant flow rate of 1.0 mL/min.

- Injection: Split mode (split ratio 1:10 to 1:100), injection volume 1 µL of diluted oil.

- Mass Spectrometer: Electron impact (EI) mode at 70 eV; ion source temperature 230°C; scan range 40-500 m/z [17] [20] [21].

- Compound Identification: Components are identified by comparing their mass spectra with reference libraries (e.g., NIST, Wiley) and by calculating and comparing their Retention Indices (RI) with literature values [20].

Protocol 2: Antimicrobial Activity Assessment

Principle: This two-part protocol determines the lowest concentration of an essential oil that inhibits visible microbial growth (MIC) and kills the microbe (MBC).

Detailed Procedure:

- Disc Diffusion (Qualitative Screening):

- Prepare Mueller-Hinton agar plates and swab with standardized inoculum of test microorganisms (e.g., S. aureus, E. coli, C. albicans).

- Impregnate sterile filter paper discs with specific volumes of the essential oil and place on the inoculated agar.

- Incubate plates at 37°C for 18-24 hours. Measure the zones of inhibition (including disc diameter) in millimeters [19] [22].

- Broth Microdilution (Quantitative MIC/MBC):

- Prepare two-fold serial dilutions of the essential oil in a suitable broth medium in a 96-well microtiter plate.

- Standardize the microbial inoculum to approximately 5 x 10⁵ CFU/mL and add to each well.

- Include growth control and sterility control wells. Cover the plate and incubate at 37°C for 18-24 hours.

- The Minimum Inhibitory Concentration (MIC) is the lowest concentration showing no visible growth.

- To determine the Minimum Bactericidal/Fungicidal Concentration (MBC/MFC), subculture broth from wells showing no growth onto fresh agar plates. The MBC/MFC is the lowest concentration yielding no growth on subculture, indicating ≥99.9% kill of the initial inoculum [19] [21].

Protocol 3: Cytotoxicity Assessment (MTT Assay)

Principle: The MTT assay measures cell metabolic activity as an indicator of cell viability and proliferation. Viable cells reduce yellow MTT to purple formazan crystals.

Detailed Procedure:

- Cell Seeding: Seed cells (e.g., Vero E6, B16, LNCaP) in a 96-well plate at a density of 1 x 10⁴ cells/well and incubate for 24 hours.

- Treatment: Treat cells with a concentration range of the essential oil (e.g., 25-100 µg/mL) and incubate for a specified period (e.g., 24-48 hours) [17] [22].

- MTT Incubation: Add MTT reagent to each well and incubate for 2-4 hours to allow formazan crystal formation.

- Solubilization and Measurement: Carefully remove the medium, dissolve the formazan crystals in DMSO, and measure the absorbance at 570 nm using a microplate reader.

- Data Analysis: Calculate cell viability as a percentage of the untreated control. The cytotoxic potential is expressed as the IC₅₀ value (concentration that inhibits 50% of cell growth) or LD₅₀ (toxic dose for 50% reduction) [17] [22].

Protocol 4: Anti-inflammatory Activity Evaluation

Principle: This protocol assesses the anti-inflammatory potential of an essential oil in a biological model by measuring its ability to downregulate key pro-inflammatory markers.

Workflow and Molecular Mechanism:

Detailed Procedure:

- In Vitro/In Vivo Model:

- In Vitro: Use macrophage cell lines (e.g., RAW 264.7) stimulated with Lipopolysaccharide (LPS).

- In Vivo: Use animal models of inflammation, such as the Complete Freund's Adjuvant (CFA)-induced arthritis model in rats [18].

- Treatment: Pre-treat or co-treat the model system with the essential oil.

- Analysis of Inflammatory Markers:

- Protein Level: Quantify the production of key pro-inflammatory cytokines (IL-1β, IL-6, TNF-α) in the supernatant or serum using Enzyme-Linked Immunosorbent Assay (ELISA) kits.

- Gene Expression Level: Isolate RNA from cells or tissue and use Reverse Transcription Quantitative Polymerase Chain Reaction (RT-qPCR) to measure the mRNA expression levels of cytokines (IL-1β, IL-6, TNF-α) and enzymes (COX-2) [18].

- Data Interpretation: A significant reduction in the levels of these markers in treated groups compared to the diseased control group indicates anti-inflammatory activity of the essential oil.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials and Reagents for EO Research

| Category | Item | Function/Application |

|---|---|---|

| Analytical Standards | Limonene, Eucalyptol, Thymol, Carvacrol, Eugenol [19] | Used as reference standards for compound identification and quantification in GC-MS. |

| Cell Culture & Cytotoxicity | Vero E6, RAW 264.7, B16, LNCaP cell lines [17] [22] [18] | In vitro models for assessing cytotoxicity and anti-inflammatory mechanisms. |

| MTT Reagent [17] [22] | Used in colorimetric assays to measure cell viability and proliferation. | |

| Microbiology | Mueller-Hinton Agar/Broth [19] [21] | Standardized medium for antimicrobial susceptibility testing. |

| Reference Strains: S. aureus (ATCC 25923), E. coli (ATCC 25922), C. albicans (ATCC 10231) [19] [22] | Quality control strains for antimicrobial assays. | |

| Molecular Biology & Immunology | ELISA Kits (for IL-1β, IL-6, TNF-α) [18] | Quantify protein levels of pro-inflammatory cytokines. |

| PCR Reagents & Primers (for IL-1β, IL-6, TNF-α, COX-2) [18] | Analyze gene expression changes in inflammatory pathways. | |

| In Vivo Models | Complete Freund's Adjuvant (CFA) [18] | Used to induce rheumatoid arthritis in animal models for anti-inflammatory studies. |

The integration of precise chemical profiling via GC-MS with robust biological screening protocols is indispensable for validating the traditional use of essential oils and unlocking their potential in modern therapeutics. The structured methodologies outlined herein—for chemical analysis, antimicrobial, cytotoxic, and anti-inflammatory evaluation—provide a reliable and reproducible framework for researchers. By establishing a clear critical link between chemical composition and bioactivity, this workflow facilitates the targeted development of standardized essential oil-based formulations for pharmaceutical, nutraceutical, and cosmetic applications. Future work should focus on elucidating synergistic interactions between components and conducting in-depth mechanistic and clinical studies.

A Step-by-Step GC-MS Protocol for Essential Oil Analysis and Bioactivity Screening

Within the framework of developing a robust GC-MS analysis protocol for plant essential oils, the sample preparation stage is paramount. The quality, composition, and bioactivity of the final analytical result are intrinsically linked to the initial extraction process [23]. Hydro-distillation remains a cornerstone technique for extracting volatile oils, prized for its simplicity and reproducibility [24] [23]. This application note provides detailed protocols for optimizing hydro-distillation and discusses the role of solvent selection in the broader context of essential oil analysis for drug development and scientific research. We summarize critical experimental data and provide step-by-step methodologies to achieve consistent, high-quality extracts suitable for subsequent GC-MS characterization.

Optimized Hydro-distillation Parameters

Hydro-distillation efficiency and essential oil yield are influenced by several controllable factors. Based on orthogonal experimental designs and single-factor tests, the following parameters have been identified as critical for process optimization.

Table 1: Key Parameters for Optimizing Hydro-distillation of Plant Essential Oils

| Parameter | Optimal Condition / Effect | Plant Model | Impact on Yield & Quality |

|---|---|---|---|

| Plant Material Pretreatment | Crushing to ~2 cm particle size [24] | Rosemary (Rosmarinus officinalis) | Increases surface area, breaking cell walls to facilitate oil release. |

| Solid-to-Liquid Ratio | 1:3 (water-to-material) [24] | Rosemary (Rosmarinus officinalis) | Maximizes yield while reducing solvent (water) consumption for economic and environmental efficiency. |

| Additive (NaCl) Concentration | 5% (w/v) [24] | Rosemary (Rosmarinus officinalis) | Improves oil yield by reducing oil solubility in the distillation water. |

| Harvest Time (HT) | 9 a.m. [25] | Spearmint (Mentha spicata L.) | Higher menthol content; exposure to sun and light (e.g., at 1 p.m. or 5 p.m.) can decrease key compound concentration. |

| Hydro-distillation Time (HDT) | 60-120 min (yield stability) [25] | Spearmint (Mentha spicata L.) | Sufficient for internal diffusion and extraction; longer times may increase energy cost without improving yield. |

| Plant Part Used | Leaves over stems [24] [26] | Rosemary (R. officinalis), Pogostemon (P. cablin) | Significant differences in volatile composition and concentration; e.g., patchouli alcohol higher in leaves [26]. |

Detailed Experimental Protocols

Standard Hydro-distillation Protocol Using a Clevenger Apparatus

This protocol is adapted from methods used for Salvia lanigera and Lavandula angustifolia [8] [27].

Research Reagent Solutions & Essential Materials

Table 2: Key Research Reagent Solutions and Materials

| Item Name | Function / Application | Specification / Note |

|---|---|---|

| Clevenger Apparatus | Essential oil separation and collection | Standard glassware setup including a still pot, condenser, and receiver with an overflow return [8]. |

| Heating Mantle / Plate | Controlled heating of the distillation flask | Adjustable temperature control is required. |

| Anhydrous Sodium Sulfate (Na₂SO₄) | Drying agent for extracted essential oil | Removes trace water from the collected oil to prevent degradation [8]. |

| Grinder or Mortar & Pestle | Plant material pretreatment | To achieve optimal particle size (e.g., ~2 cm) [24]. |

| Analytical Balance | Precise weighing of plant material and reagents | Critical for accuracy in solid-to-liquid ratio and additive concentration. |

| Distilled Water | Extraction solvent | Prevents introduction of contaminants. |

Procedure:

- Plant Material Preparation: Collect fresh aerial parts of the plant. Rinse if necessary and air-dry to remove surface moisture. For rosemary, crush the leaves to an approximate size of 2 cm [24].

- Loading: Weigh 200-500 g of prepared plant material and place it in the round-bottom flask of the Clevenger apparatus [8]. Add distilled water at the optimized solid-to-liquid ratio (e.g., 1:3 for rosemary) [24]. For optimization, add 5% (w/v) NaCl to the water [24].

- Distillation: Assemble the apparatus securely to prevent vapor escape. Apply heat to the flask and bring the mixture to a steady boil. Maintain a consistent distillation process for the predetermined time (e.g., 2-3 hours, or until no more oil is collected) [24] [8].

- Collection & Drying: The essential oil and water vapor will condense in the condenser and separate in the receiver. The essential oil, being less dense than water, will be collected in the side arm. Collect the oil and transfer it to a vial containing ~1 g of anhydrous sodium sulfate to remove any residual water [8].

- Storage: Store the dried essential oil in an amber glass vial at 4°C to preserve its volatile compounds until GC-MS analysis [8].

Protocol Variant: Microwave-Assisted Hydro-Distillation (MAHD)

MAHD offers advantages including shorter extraction times and higher efficiency for some plant materials [28] [27].

Procedure:

- Preparation: Weigh 100 g of dried plant material and moisten it with 500 mL of distilled water in the microwave extraction vessel [27].

- Extraction Setup: Place the vessel in the microwave digestion system. Set the power and temperature program. For example, for lavender, the power was set to 1000 W, with the temperature raised to 100°C in 10 minutes and maintained for 30 minutes [27]. For Rumex crispus, optimal conditions were 535 W for 23 minutes [28].

- Collection: After the cycle is complete, collect the essential oil from the attached condenser or separator. Dry and store as described in the standard protocol.

The workflow below illustrates the logical progression and decision points in the sample preparation process.

The optimization of hydro-distillation is a critical first step in ensuring the reliability and accuracy of subsequent GC-MS analysis in plant essential oil research. By systematically controlling parameters such as plant material pretreatment, solid-to-liquid ratio, additive use, and distillation time, researchers and drug development professionals can maximize the yield and fidelity of the volatile profile extracted. The protocols and data summarized here provide a concrete foundation for developing standardized, efficient, and cleaner sample preparation techniques essential for high-quality phytochemical research.

Gas Chromatography-Mass Spectrometry (GC-MS) is a cornerstone analytical technique for the analysis of plant essential oils, providing unparalleled separation power coupled with sensitive and selective detection [29] [30]. The reliability of the results, however, is profoundly dependent on the appropriate configuration of two critical components: the GC column and the oven temperature program. For researchers in pharmacology and drug development, a meticulously optimized GC-MS protocol is essential for accurately profiling the complex mixture of volatile and semi-volatile compounds—such as monoterpenes, sesquiterpenes, and their oxygenated derivatives—found in essential oils [14] [31]. This application note, framed within a broader thesis on GC-MS analysis of plant essential oils, provides detailed protocols and data-driven recommendations for instrument configuration to ensure reproducible, high-quality results.

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table details key reagents and materials essential for the sample preparation and GC-MS analysis of plant essential oils.

Table 1: Key Research Reagent Solutions for Essential Oil GC-MS Analysis

| Item | Function/Application | Citation |

|---|---|---|

| Rxi-5MS Capillary Column | A mid-polarity (5% diphenyl / 95% dimethyl polysiloxane) standard phase for general essential oil analysis; provides good separation of a wide range of volatiles. | [14] |

| HP-INNOWAX Capillary Column | A polar (polyethylene glycol) stationary phase used for complementary analysis to resolve oxygenated compounds and polar constituents. | [14] |

| DB-5MS Capillary Column | A low-polarity (5% phenyl / 95% dimethyl polysiloxane) phase, equivalent to Rxi-5MS, commonly used for metabolic profiling. | [32] [33] |

| Magnesium Aluminometasilicate | An excipient material used during hydrodistillation or extraction to significantly increase the yield of essential oil and alter the relative abundance of specific compounds like sabinene. | [31] |

| Ethyl Acetate | A common solvent for diluting essential oil samples prior to GC-MS injection to ensure proper chromatography and prevent instrument contamination. | [34] |

| High-Purity Helium | The standard carrier gas used in GC-MS to transport vaporized samples through the chromatographic column. | [33] |

| QuEChERS Salt Mixtures | Salts like magnesium sulfate used in a solvent extraction technique for samples, facilitating phase separation for the analysis of pesticides or contaminants. | [35] |

| Solid Phase Microextraction (SPME) Fiber | A solvent-less extraction technique where a coated fiber is exposed to the sample headspace to absorb volatile analytes for thermal desorption in the GC injector. | [35] |

| NIST Mass Spectral Library | A comprehensive database of reference mass spectra used to identify unknown compounds by comparing their fragmentation pattern with known standards. | [34] [30] |

Column Selection for Essential Oil Analysis

The selection of a gas chromatographic column is a primary determinant of the separation efficiency for the complex constituents of essential oils. The stationary phase chemistry, column dimensions, and film thickness directly influence the resolution of individual analytes.

Stationary Phase Chemistry

The choice of stationary phase polarity is critical for resolving different chemical classes within an essential oil. Using columns of differing polarities provides a more comprehensive compositional profile [14] [30].

- Non-Polar to Mid-Polar Phases (Rxi-5MS, DB-5MS): These columns, with (5% phenyl)-methylpolysiloxane chemistry, are the most widely used workhorses for essential oil analysis. They separate compounds primarily based on their boiling points and are excellent for resolving hydrocarbon terpenes (monoterpenes and sesquiterpenes) [14] [33].

- Polar Phases (HP-INNOWAX): Polyethylene glycol (PEG) columns offer a different selectivity, particularly effective for separating polar, oxygenated compounds such as alcohols, aldehydes, and ketones. This complementary selectivity is vital for accurately profiling key odor-active and bioactive molecules [14].

Comparative studies on Dendranthema indicum var. aromaticum essential oil demonstrate this distinction clearly. The research identified 90 compounds using the Rxi-5MS column versus 78 using the HP-INNOWAX column, with notable differences in the observed proportions of compound categories [14].

Table 2: Comparative Analysis of Compound Categories on Different Stationary Phases

| Compound Category | Rxi-5MS (% Composition) | HP-INNOWAX (% Composition) |

|---|---|---|

| Oxygenated Monoterpenes | 28.76 - 77.27% | 28.67 - 78.10% |

| Oxygenated Sesquiterpenes | 4.27 - 38.06% | 9.17 - 38.06% |

| Sesquiterpenes | 3.22 - 11.57% | 6.99 - 11.57% |

| Monoterpenes | 0 - 3.32% | 0 - 0.98% |

Column Dimensions and Film Thickness

- Length, Diameter, and Film Thickness: A detailed protocol for the analysis of Brassica oleracea utilizes a DB-5MS column (30 m × 0.25 mm i.d. × 0.25 µm film thickness) [33]. These dimensions represent a common standard.

- A 30-meter length offers a good balance between analysis time and resolution.

- A narrow internal diameter (0.25 mm) enhances separation efficiency.

- A 0.25 µm film thickness is suitable for a wide range of volatiles, providing adequate retention and release of analytes without excessive analysis times.

Oven Temperature Programming

A well-designed temperature program is crucial for separating the wide range of compounds in essential oils, which have varying volatilities from highly volatile monoterpenes to less volatile sesquiterpenes and their derivatives.

Protocol: Temperature Program for Comprehensive Essential Oil Profiling

The following protocol, adapted from methodologies used for Brassica oleracea and Myristica fragrans (nutmeg), provides a robust starting point for most essential oils [31] [33].

- Initial Temperature: 36°C

- Initial Hold Time: 5 minutes. This extended hold at a low temperature allows for the effective focusing and separation of the most volatile components at the head of the column.

- Ramp 1: 4°C per minute to 150°C. This shallow, gradual ramp is critical for resolving complex mixtures of monoterpenes and sesquiterpenes that co-elute with simpler programs.

- Ramp 2: 20°C per minute to 250°C. A steeper ramp quickly elutes higher-boiling-point compounds, reducing total run time.

- Final Temperature: 250°C

- Final Hold Time: 5-10 minutes. This bake-out step ensures that all heavy compounds are cleared from the column, preventing carryover into subsequent runs.

Impact of Extraction Method on Observed Composition

The temperature and conditions used during essential oil extraction (e.g., Hydrodistillation, Microwave-Assisted Extraction, Headspace) influence the volatile profile introduced to the GC system. Consequently, the optimal GC temperature program may require slight adjustments based on the sample preparation method [14].

Table 3: Influence of Extraction Method and Temperature on Oil Composition

| Extraction Method | Key Extraction Conditions | Impact on Recovered Oil Composition |

|---|---|---|

| Headspace (HS) | Lower temp (90°C), sealed system, shorter time (20 min) | Highest levels of volatile oxygenated monoterpenes and monoterpenes; lowest levels of higher-boiling sesquiterpenes. |

| Hydrodistillation (HD) | High temp (100°C), open system, long time (4 h) | Higher proportions of sesquiterpenes and oxygenated sesquiterpenes due to prolonged heating. |

| Microwave-Assisted (MAE) | Solvent recycling under vacuum | Lower amounts of volatile monoterpenes due to potential loss under vacuum conditions. |

Integrated Experimental Workflow

The following diagram illustrates the complete experimental workflow for the GC-MS analysis of plant essential oils, from sample preparation to data interpretation.

Data Analysis and Compound Identification

Following data acquisition, processing and interpretation are critical. Modern benchtop GC-MS systems typically offer three primary modes of data analysis [29]:

- Total Ion Chromatogram (TIC): A universal chromatogram constructed by summing all ion signals detected throughout the run. It is powerful for qualitative analysis, as the mass spectrum at any point can be interpreted or searched against spectral libraries [29].

- Extracted Ion Chromatogram (EIC): A selective chromatogram generated by plotting the signal of a specific ion or set of ions. This is used to confirm the presence of a target compound based on its characteristic fragments and to reduce background interference [29].

- Selected Ion Monitoring (SIM): A highly sensitive quantitative experiment where the mass spectrometer is programmed to detect only a pre-selected set of ions for specific target analytes. This significantly reduces noise and lowers detection limits compared to full-scan TIC analysis [29] [30].

For confident identification, a compound's retention time and mass spectrum should be compared to an authentic standard analyzed under identical conditions. When standards are unavailable, a combination of retention index matching and mass spectral library searching (e.g., NIST, Wiley) provides a high level of confidence [34] [30]. Advanced techniques like exact mass GC-MS using Orbitrap technology can further resolve ambiguities by providing elemental composition information from accurate mass measurements [32].

In the context of a broader thesis on GC-MS analysis of plant essential oils, the optimization of injection parameters is a critical step in method development. The inlet system serves as the gateway for the sample into the gas chromatograph, and its parameters—temperature, split ratio, and injection volume—directly impact method sensitivity, resolution, and accuracy. For complex matrices like plant essential oils, which contain volatile terpenes, esters, and other biologically active compounds, proper inlet configuration is essential for obtaining reliable, reproducible results that support drug development research. This protocol details a systematic approach to optimizing these key injection parameters for the analysis of essential oils, drawing on current research and established analytical principles.

Optimization of Critical Injection Parameters

The following section summarizes the core injection parameters requiring optimization and presents experimental data from recent studies.

Table 1: Summary of Key GC-MS Injection Parameters and Their Effects

| Parameter | Typical Range for Essential Oils | Impact on Analysis | Considerations for Method Development |

|---|---|---|---|

| Inlet Temperature | 250–290 °C | Ensures complete vaporization of analytes; prevents thermal degradation [36] [37]. | Must be high enough for high-boiling point compounds (e.g., sesquiterpenes) but not cause decomposition [38]. |

| Split Ratio | 10:1 to 50:1 | Controls the amount of sample entering the column; reduces solvent effects and column overloading [36] [39]. | A higher ratio is used for concentrated samples; splitless mode may be needed for trace analysis [40]. |

| Injection Volume | 0.5–2.0 µL | Affects detection limits and peak shape [41]. | Must be optimized in conjunction with split ratio and sample concentration to prevent column damage or peak distortion. |

Inlet Temperature Optimization

The injector temperature must be sufficiently high to instantly vaporize the entire sample without causing thermal decomposition of target analytes. For essential oil analysis, which encompasses a wide range of volatilities, a temperature between 250 °C and 290 °C is commonly employed.

- Evidence from Plant Volatiles Analysis: A method for analyzing herbivore-induced plant volatiles, including sesquiterpenes, utilized an injector temperature of 290 °C to ensure the vaporization of a broad spectrum of compounds [42].

- Evidence from Sterol Analysis: A GC-MS method for multi-component sterols in complex food matrices also used an injector temperature of 290 °C, demonstrating its applicability for less volatile compounds within plant-derived products [36].

A temperature that is too low can lead to incomplete vaporization, resulting in peak broadening, tailing, and poor reproducibility. Conversely, excessive temperatures can degrade thermally labile compounds. If analyzing essential oils rich in sensitive components, initial method development should test a range of temperatures (e.g., 240, 260, 280 °C) while monitoring for degradation products or loss of resolution.

Split Ratio and Injection Volume Optimization

The split ratio and injection volume work in tandem to control the mass of sample reaching the analytical column. This is crucial for achieving good peak shape and preventing overloading, which is a common issue with concentrated essential oil samples.

- Standard Sterol Method: A developed GC-MS protocol for sterols used a 10:1 split ratio with an injection volume of 1.0 µL, a balanced approach for a complex matrix [36].

- Allergen Analysis in Cosmetics: An optimized method for 28 fragrance allergens in personal care products utilized a splitless injection mode to achieve high sensitivity for trace-level compounds, followed by a high split ratio during the solvent venting phase to protect the column from solvent overload [39]. This highlights that the initial split state can be dynamically programmed.

- Trade-offs in Metabolomics: A study on untargeted GC-MS metabolomics directly evaluated the trade-off between analysis speed and metabolite coverage/repeatability [41]. While it did not alter injection volume, it underscored that all parameters affecting chromatographic performance (like those governing injection) must be optimized for the specific analytical goal—whether high throughput or maximum analytical depth.

For a typical undiluted essential oil, a split ratio of 10:1 to 50:1 with a 1 µL injection is a recommended starting point. For more diluted samples or trace analysis, a lower split ratio or splitless injection with a larger injection volume (e.g., 2 µL) may be necessary to improve sensitivity.

Experimental Protocol: Inlet Optimization for Myrtle Essential Oil

Objective: To determine the optimal inlet temperature, split ratio, and injection volume for the GC-MS analysis of Myrtus communis L. essential oil to maximize sensitivity and resolution of key compounds like α-pinene, 1,8-cineole, and linalyl acetate.

Materials and Reagents

Table 2: Research Reagent Solutions and Essential Materials

| Item | Function / Application | Example / Specification |

|---|---|---|

| Myrtle Essential Oil | Analytical Sample | Authentic, pure essential oil from Myrtus communis L., stored at -20 °C [37]. |

| n-Alkane Series (C8-C28) | Retention Index (RI) Calibration | For precise identification of compounds by comparing their RI with literature values [37]. |

| n-Hexane | Sample Dilution Solvent | HPLC-grade solvent for preparing serial dilutions of the essential oil [36]. |

| DB-5MS Capillary Column | GC-MS Separation | (5%-phenyl)-methylpolysiloxane phase; common dimensions: 30 m x 0.25 mm i.d. x 0.25 µm film thickness [36] [39] [37]. |

| Helium Carrier Gas | Mobile Phase | High-purity (99.999%) helium, used at a constant flow rate (e.g., 1.0 mL/min) [36] [37]. |

| Phenylboronic Acid (PBA) | Derivatization Reagent | Used in other contexts (e.g., 3-MCPD analysis) to improve volatility of target analytes; not required for standard essential oil analysis [40]. |

| QuEChERS Extraction Kits | Sample Preparation | For cleanup of complex matrices; may not be necessary for pure essential oils but is critical for pesticide analysis in plant materials [43]. |

Instrumental Configuration

- GC-MS System: Agilent 7890B GC coupled with a 5977A MSD (or equivalent).

- Column: DB-5MS UI (30 m × 250 µm × 0.25 µm).

- Oven Program: Initial 60°C (hold 1 min), ramp at 4°C/min to 210°C, then at 20°C/min to 240°C (hold 8.5 min) [37]. Adapt as needed for specific separation.

- MS Conditions: Electron Impact (EI) ionization at 70 eV; ion source temperature 230°C; acquisition in Scan mode (m/z 45-550) [38] [37].

Optimization Procedure

- Sample Preparation: Prepare a 1:100 (v/v) dilution of the myrtle essential oil in n-hexane.

- Baseline Method: Set initial parameters as Inlet Temperature: 250°C, Split Ratio: 20:1, Injection Volume: 1.0 µL.

- Inlet Temperature Study: Inject the sample using the baseline method, but vary the inlet temperature: 240°C, 260°C, 280°C. Monitor the peak shape (symmetry, width) and area of early-eluting (e.g., α-pinene) and late-eluting, thermally sensitive (e.g., linalyl acetate) compounds. A sudden drop in the peak area of sensitive compounds at higher temperatures indicates degradation.

- Split Ratio Study: Using the optimal temperature from step 3, keep the injection volume at 1.0 µL and test split ratios of 10:1, 20:1, and 50:1. Evaluate the sensitivity (peak height) and resolution of co-eluting peaks. The goal is to find the ratio that provides sufficient sensitivity without causing peak fronting due to column overloading.

- Injection Volume Study: Using the optimal temperature and split ratio, test injection volumes of 0.5 µL, 1.0 µL, and 2.0 µL. Assess the signal-to-noise ratio and the effect on peak shape, particularly for the solvent peak and early-eluting analytes.

- Validation: Once optimal parameters are selected, perform six consecutive injections of the same sample to determine the repeatability of the retention times and peak areas, expressed as Relative Standard Deviation (RSD%). The method is acceptable if RSD is typically < 2-3% for retention times and < 5% for peak areas [38].

The logical workflow for this optimization process is summarized below.

The systematic optimization of inlet temperature, split ratio, and injection volume is a foundational requirement for developing a robust and reliable GC-MS method for plant essential oil analysis. The parameters are interdependent and must be fine-tuned for the specific chemical profile of the oil under investigation. Adherence to the protocols and considerations outlined in this document will provide researchers and drug development scientists with a method that delivers high-quality, reproducible data, thereby supporting downstream applications in quality control, standardization, and bioactivity assessment of plant-derived substances.

Gas chromatography-mass spectrometry (GC-MS) has become an indispensable analytical technique for the characterization of plant essential oils, providing critical data for chemotaxonomic studies, bioactive compound discovery, and quality control in pharmaceutical and fragrance industries. The analytical fidelity of GC-MS analysis is profoundly influenced by two fundamental instrumental parameters: ionization energy and ion source temperature. Within the context of a broader thesis on GC-MS analysis of plant essential oils, this application note provides detailed protocols for the optimization of these parameters, supported by experimental data from recent studies. Proper optimization of these parameters enhances molecular ion detection, controls fragmentation patterns, and ensures the reproducibility of results—factors crucial for accurate compound identification in complex essential oil matrices [14] [19] [44].

Theoretical Background

Electron Ionization (EI) in GC-MS

Electron Ionization (EI) is the most prevalent ionization technique in GC-MS analysis. In a conventional EI source, analyte molecules in the gas phase are bombarded with high-energy electrons (typically 70 eV) emitted from a heated filament. This collision ejects an electron from the analyte molecule, forming a radical cation (M⁺•). The excess energy from this process causes reproducible fragmentation, generating a mass spectrum that serves as a chemical fingerprint for compound identification using standard libraries [45] [46].

The standard 70 eV energy is used because it represents a plateau of ionization efficiency for most compounds, ensuring consistent fragmentation patterns across different instruments. However, the energy required to remove an electron from typical organic molecules is only 8-12 eV. The significant excess energy causes extensive fragmentation, which can be detrimental for detecting the molecular ion, a critical piece of information for confirming compound identity [46] [47].

Role of Ion Source Temperature

The ion source temperature must be carefully optimized to prevent the condensation of analytes within the source while avoiding thermal degradation of labile compounds. A properly heated source ensures that analytes remain in the gas phase for ionization and helps volatilize contaminants that could otherwise lead to signal suppression and reduced sensitivity. Modern extractor and high-efficiency ion sources are designed to operate effectively up to 350°C, but the optimal temperature depends on the specific application and analyte properties [48].

Table 1: Key Mass Spectrometry Parameters and Their Effects on Analysis

| Parameter | Typical Range | Primary Function | Impact on Essential Oil Analysis |

|---|---|---|---|

| Ionization Energy | 10-70 eV | Controls analyte fragmentation | Higher energy (70 eV) provides library-compatible spectra; lower energy (20-30 eV) enhances molecular ion intensity |

| Ion Source Temperature | 200-350°C | Maintains analytes in gas phase, prevents condensation | Prevents thermal decomposition of labile terpenoids while ensuring sensitivity |

| Quadrupole Temperature | 150-200°C | Mass separation and filtering | Typically maintained at 150°C for stability; higher temperatures occasionally used for high-boiling compounds |

Optimization of Ionization Energy

Standard 70 eV Protocol

Principle: The 70 eV electron energy has been established as the standard for EI mass spectrometry because it produces abundant, reproducible fragmentation that enables reliable library matching. At this energy, the ionization efficiency reaches a plateau for most compounds, making spectral patterns consistent across different instruments and laboratories [46] [47].

Experimental Protocol:

- Set the ionization energy to 70 eV in the MS method parameters

- Ensure the emission current is typically between 50-250 µA (instrument dependent)

- For essential oil analysis, use a mass range of m/z 40-500 to cover monoterpenes to sesquiterpenes

- Employ a solvent delay of 2-3 minutes to prevent filament damage and source contamination

- Acquire data in full-scan mode for untargeted profiling of essential oil components

Application Note: In the analysis of Dendranthema indicum var. aromaticum essential oil, 70 eV ionization successfully identified 115 volatile compounds, primarily oxygenated monoterpenes (28.76-78.10%) and oxygenated sesquiterpenes (4.27-38.06%). The major constituents—α-thujone, β-thujone, cis-sabinol, sabinyl acetate, and (-)-neointermedeol—were confidently identified through library matching of their fragmentation patterns [14].

Low Energy Electron Ionization (20-30 eV)

Principle: Reducing the electron energy to 20-30 eV decreases the internal energy transferred to the molecular ions during ionization, thereby reducing fragmentation. This "softer" ionization enhances the abundance of the molecular ion, which is particularly valuable for confirming the molecular weight of unknown compounds or analyzing compounds that exhibit excessive fragmentation at 70 eV [47] [49].

Experimental Protocol:

- Set the ionization energy to 20-30 eV in the MS method parameters

- Increase the emission current (if possible) to compensate for reduced ionization efficiency

- Allow additional tuning time as low-energy conditions require stabilization

- Consider using a lower ion source temperature (approximately 200°C) to further reduce fragmentation

- Note that mass spectra acquired at low eV may not be directly comparable to standard 70 eV libraries

Application Note: Research on estrogenic compounds demonstrated that reducing electron energy from 70 eV to 20 eV significantly enhanced the abundance of molecular ions. This improvement translated to a 1.1- to 4.6-fold gain in instrumental sensitivity in GC-MS/MS mode, enabling the detection of these compounds at the low ng/L levels required by environmental regulations [47].

Cold Electron Ionization

Principle: Cold EI is an advanced technique based on electron ionization of vibrationally cold molecules in supersonic molecular beams (SMB). The vibrational cooling of analytes occurs through their expansion in helium into a vacuum chamber, resulting in reduced fragmentation and significantly enhanced molecular ions while maintaining the characteristic fragmentation patterns needed for identification [49].

Experimental Protocol:

- Interface the GC with the MS using a supersonic molecular beam apparatus

- Use helium make-up gas to achieve total flow rates of approximately 60 mL/min

- Maintain the supersonic nozzle temperature between 250-300°C

- Apply 70 eV electrons for ionization of the vibrationally cold molecules

- Utilize the enhanced molecular ions for improved identification and quantification

Application Note: Cold EI has demonstrated remarkable enhancement of molecular ions for compounds that typically show little to no molecular ion in conventional EI. For example, in the analysis of n-tetracosane (n-C₂₄H₅₀), cold EI enhanced the molecular ion abundance by over 100-fold compared to standard EI, while maintaining compatibility with NIST library searches [49].

The following diagram illustrates the decision pathway for selecting the appropriate ionization energy based on analytical goals:

Optimization of Ion Source Temperature

Fundamental Considerations

The ion source temperature must balance two competing factors: sufficient heat to prevent analyte condensation and volatilize contaminants versus excessive heat that may cause thermal degradation of labile compounds. Most essential oil components, including monoterpenes, sesquiterpenes, and their oxygenated derivatives, have relatively high vapor pressures, but some thermally labile compounds may degrade if source temperatures are too high [48].

Experimental Protocol for Temperature Optimization:

- Begin with a manufacturer-recommended default temperature (typically 230-250°C)

- Analyze a standard mixture containing both low-boiling and high-boiling compounds

- Monitor the signal-to-noise ratio for target compounds and the overall total ion current

- Check for signs of thermal degradation (unexpected peaks, decreased target compound response)

- Adjust temperature in 10-20°C increments to optimize sensitivity and stability

- Maintain the transfer line temperature equal to or slightly above the ion source temperature to prevent cold spots

Application Note: For routine analysis of essential oils, a source temperature of 265-275°C often provides an optimal balance between sensitivity and compound stability. When analyzing essential oils containing thermally labile compounds such as certain aldehydes or esters, lower temperatures (230-250°C) may be preferable. In the analysis of Jatropha species essential oils, successful characterization of 95 volatile constituents was achieved with appropriate temperature control, revealing predominant chemical classes including fatty acid esters, sesquiterpenes, and diterpenes [44].

Temperature Effects on Spectral Quality and Sensitivity

The ion source temperature influences not only the stability of analytes but also the spectral quality and distribution of ions. Higher source temperatures can increase the internal energy of molecules prior to ionization, potentially leading to increased fragmentation. This phenomenon is particularly noticeable in the analysis of perfluorotributylamine (PFTBA), commonly used for instrument tuning, where higher temperatures increase the abundance of low-mass fragments (m/z 69) while decreasing the relative abundance of high-mass ions (m/z 502) [48].

Table 2: Optimized Ion Source Temperature Guidelines for Essential Oil Analysis

| Essential Oil Type | Recommended Source Temperature | Rationale | Key Compounds |

|---|---|---|---|

| High Monoterpene Oils (e.g., Citrus) | 230-250°C | Prevents degradation of light hydrocarbons | Limonene, pinene, myrcene |

| Oxygenated Monoterpene Oils (e.g., Lavender) | 250-270°C | Ensures vaporization of linalool, linalyl acetate | Linalool, linalyl acetate, camphor |

| Sesquiterpene-Rich Oils (e.g., Cedarwood) | 270-300°C | Higher temp needed for heavier compounds | Cedrol, thujopsene, sesquiterpene alcohols |

| Complex Blends with High-Boiling Compounds | 280-300°C | Prevents condensation of less volatile components | Phytol, fatty acid esters, waxes |

Integrated Method Development for Essential Oil Analysis